Rotorway Two Seat Kit Helicopter Kit

To many of us, the essence of the word “freedom” means the ability to go anywhere at virtually any time that we choose. To many more of us, that word is epitomized by what we feel as we fly from place to place; in search of adventure, enlightenment, fun and a clear view of the rest of our world.

Airport by airport . . . but think of how wonderful it would be if we weren’t so de pendent on having a half mile or so of concrete, macadam, asphalt, etc. to land on. Now, that sounds like freedom to me!

FREEDOM! Just think of it . . . the ability to rise effortlessly and vertically from most any location, speeding along at near 100 mph in a safe and economical manner, cruising around without benefit of wings but accompanied by the healthy beat of a finely tuned rotor system.

Alighting in places so small that even the best STOL aircraft would fear the consequences of a landing … or using a flotation system to splash easily into some remote fishing hole or mountain lake.

This is the real freedom that is made possible by the use of a helicopter. “But wait a minute there, Jimbo. Helicopters cost, hundreds of thousands of dollars—right? And don’t they need lots of costly maintenance?”

“And don’t they require awesome piloting skills and expensive lessons. . ?” Not necessarily so, rotor breath! Especially if you happen to be acquainted with the Rotorway Exec kit helicopter. The Exec is evidently the only realistic avenue to afford able helicopter ownership, available to the common man.

And please note that I am not even hazarding the serious mention of rebuilding of an older, used helicopter—take my word for it, those kinds of projects are hardly a bargain. Helicopters are voracious money eaters — with one very notable exception — that being the Lone Exec . . . the only successful commercially offered helicopter kit available to the rotorhead who doesn’t own (or rob) their own bank.

DIY Helicopter Kits

A KIT helicopter, though? Has this Campbell guy finally slipped his gourd . . . wouldn’t a kit helicopter be dangerous, difficult to build, and fly real squirrelly (EVEN without Campbell flying it)? Questions, questions, questions. . . .

Well kiddies; I’ve been a helicopter pilot for several years now (proof positive that anyone can fly an egg-beater — with a little practice!) — an experience that teaches one caution, humility, pride, and an eye for detail that becomes the very essence of survival. Such whirly-wipged craft are wondrous devices that offer awesome capabilities and exception al versatility.

But they are also remarkably subject to the whims of neglect or indifference. The easiest way to get hurt in this business is to take a nonchalant, devil-may-care attitude about helicopter flying — such will get you hurt in a hurry.

Still; properly flown and maintained, these devices are some of the most challenging and enjoyable beasts of burden that I have ever flown and their appeal (to me) borders on the fanatical. I love flying helicopters — even though every part of these damned things seems to be trying to tear itself limb from limb (while doing the same to its occupants).

I have never learned more, or had nearly as much demanded from me, as I have had while flying helicopters. It is an esoteric and elite pursuit. Be that as it may, the concept of a homebuilt kit helicopter did indeed tend to make me look askance and shake my head with portents of dread for those erstwhile fools that might attempt such a foreboding assignment.

Such a complex and intricate piece of machinery was not the kind of thing that I would think should be trusted to amateurs. . . . I’ve changed my mind, though. Enter B. J. Schramm and the Rotorway Exec — the only feasible, enjoyable . . . and SAFE kit helicopter that I know of.

A statement that I once thought to be impossible — until I got up the courage to research this little devil myself and find out why so many of them are being built and FLOWN by builders with no significant prior helicopter building or flying credentials.

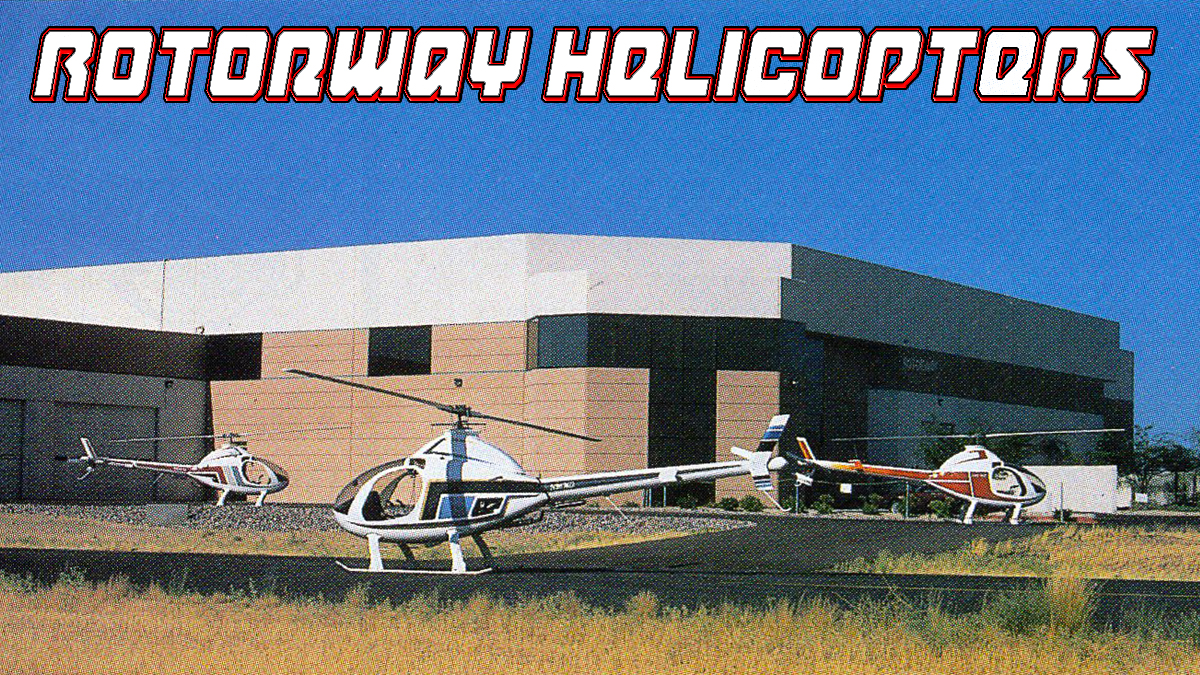

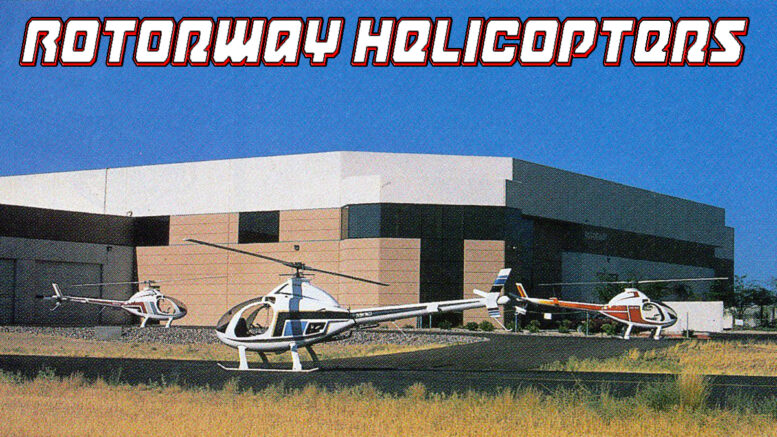

The Rotorway Exec is the latest in a long line of flying machines that have been manufactured in Chandler, a small suburb of Phoenix, Arizona. Like many of the best designers in this business, the rotary minded Mr. Schramm is a precision tinkerer — a man in search of a better and more feasible way to arrive at a solution — the current Exec displays the results of his many years of research.

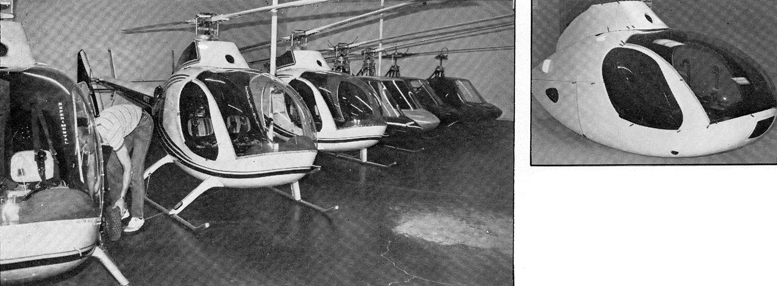

LEFT: Some of the seven kit sections ready to head off to lucky builders all over the world.

RIGHT: Ken Clarke displays part of the tail rotor drive and control housing.

The Rotorway Exec helicopter is the sweaty product of nearly 30 years of research, seven different designs, at least ten engine changes, and more concerted design, engineering, and manufacturing talent than I have ever seen demonstrated by a company in the sport aviation business — and the story ain’t over yet, kiddies.

The Exec helicopter kit is not a toy, a model, or some slight pretender to the throne of rotory winged flight. It is a full fledged helicopter with some very interesting and noteworthy capabilities that some of the certificated, $150,000, ready to fly wonders, cannot equal.

The Rotorway Exec is a two-place helicopter powered by the Rotorway RW 152 — a liquid-cooled 4-stroke engine that was designed, tested and subsequently manufactured by the Rotorway bunch (and if you think building the helicopters is a sweet trick—try designing and building the engine for it!).

Over ninety-five percent of the parts in the Rotorway Exec kit are actually manufactured on premises — along side those that they also fabricate for some of the biggest names in the aerospace game.

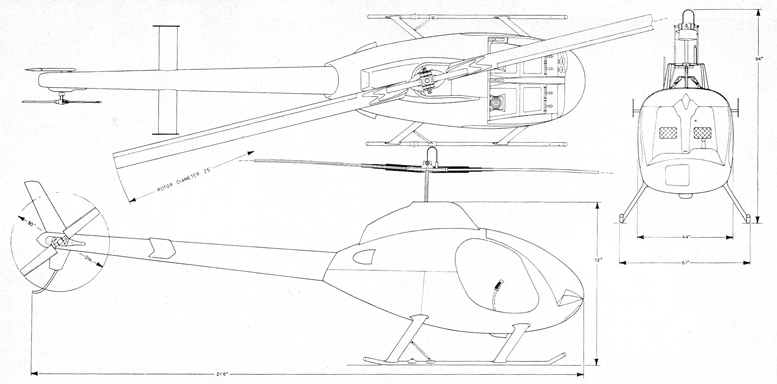

The Exec runs on auto gas, cruises just under 100 mph, climbs over 1000 feet per minute and can be retrofitted with floats or even a small crop dusting rig. It utilizes a two-blade semi-rigid rotor system, oxy acetylene welded steel frame, aluminum monococque tail boom, and composite fuselage shells.

The kit is made available in seven primary kit groups with a total price tag just a tad under thirty thousand smackers. The kit is extremely well documented with well detailed drawings, manuals and numerous sets of “see/do” pictures that serve nicely to clear up confusion.

Also, personnel are available during normal business hours to answer builder’s questions. A series of options are avail able that can decrease some of the more esoteric construction steps (such as welding) as well as increase the versatility of the Exec.

Don’t let anyone kid you. Pre-flight inspection is the most critical part of safe helicoptering.

A new elastomeric rotor head is now available that has done wonders for the handling of this aircraft and though it adds several thousand big ones to the cost of the EXEC, I must recommend it highly—it is a significant addition to the Exec helicopter package.

Floats cost approximately $3500, and a crop dusting rig goes for about $3000. As part of each kit purchase, Rotorway includes a series of lessons at its Chandler based flight school in real Execs, built and maintained by the factory.

As builders near that momentous first flight, they are taken through the rudiments of pre-flight, basic aerodynamics, Exec maintenance, hovering, and rudimentary flight skills. After one gets their ship flying and becomes proficient at basic flying skills, the owner returns and receives the balance of their flight training.

Parts & Pieces

The standard helicopter rotor head apparently works well but I must emphatically recommend the newer elastomeric rotor head. It’s a beaut. If you want one of these things — don’t spare the extra expense — get this head! This head uses a sliding swash plate instead of a series of push-pull cables to control collective pitch.

The elastomeric bearings in use with this rotor system is a bonded rubber assembly that sports alternating layers of rubber and brass all melded together en masse. This collection absorbs many of the pressures of centrifugal force due to the absorbing nature of the rubber elements.

One of Rotorway’s Execs undergoing inspection prior to being returned to service with the flight school.

This unit uses less components than the aforementioned system, and is basically more reliable due to its simplicity. The use of asymmetrical airfoils on the main rotor blades tends to produce more lifting power and is a feature normally found on more expensive turbine helicopters.

The Rotorway Exec uses a unique powerplant that was designed, built, and tested right at the factory. Each and every engine is manufactured to stringent tolerances and is shipped to the builder, factory assembled and tested (on a special test stand). The 175-pound, liquid-cooled RW 152 produces 152 horsepower and uses auto or aviation fuel at the pilot’s discretion.

This engine has compiled a fairly reliable record thus far, and I would love to see it adapted and made available for fixed wing, experimental, aircraft usage. I would imagine that this engine might possibly be manufactured affordably to solve many of the problems home builders are having in getting decent and affordable engines. How about it, Mr. Schramm? The industry needs it.

The helicopter cockpit is about as roomy as a VW beetle — which ain’t saying much if you have to fly it with the doors closed. Thankfully, flight with the doors removed is both allowable and encouraged — thus allowing for a bit more elbow room (and some cheap air conditioning — most welcome in the warm climes of Arizona).

Cockpit head room is limited but still adequate for a wide range of pilot sizes — requiring one to assume a posture appropriate to their dimensions. Leg room (as long as you haven’t had to slouch too badly) is fairly plentiful.

LEFT: Part of the Rotorway flight school line-up. They do a good deal of training here.

RIGHT: Kind of looks like a summer home for “E.T.” doesn’t it?

Panel room is limited but considering the very VFR nature of the EXEC, it actually works out to be more than adequate for all the normal instruments and a radio or two as well as an extra instrument, as desired. Taking the left seat, I noted that the deeply recessed instrument panel positioning still allowed for easy viewing and adequate separation from possible distractions.

The anti-torque pedals (something akin to the rudder pedals in a fixed wing beasty — but a touch more responsive than anything the airplane jocks may be used to) are set well forward and can be adjusted to help fit the individual needs of the occupant.

The dual control set-up positions the left collective lever right next to the edge of the door and the right one, snugly between the seats. Cyclic pitch control sticks are a well curved appendage that clears even a tubby gut like mine very nicely and seems to be positioned extremely well.

Seat belts and shoulder harnesses are installed handily and allow for a bit of added security to those not used to being so close to an open door (though this particular aerial voyer really likes such seating — what can I say? I had a warped childhood — sorry MOM . . .).

The starting sequence offers few surprises. The liquid-cooled Rotorway RW 152 helicopter engine started readily and settled into a very steady and low vibration idle that barely got the water temp gauge out of the sack.

My check pilot cautioned me that the Rotorway Exec was sure to show me a few new tricks during my flight test, so he would introduce me to the machine by demonstrating a few of the basic maneuvers beforehand and then start handing the bird over to my clumsy control.

Despite the warm morning (nearly 90 degrees), I was surprised to note that we didn’t have to wrap the throttle way up to achieve hover and that there seemed to be plenty of power available even with the both of us aboard and a near full fuel load.

The Exec helicopter responded well despite the fact that this morning was a very gusty affair that threatened some more interesting moments for the latter part of my flight test. A bit of hovering was followed by minor maneuvering among the landing pads and some pedal turns prior to my getting my hands on the beast.

Helicopters do require good control coordination — mostly because they tend to have a mind of their own and firm plans to keep it that way. The fore/aft and side to side movement is controlled by the center cyclic control stick.

Moving it fore and aft, or to either side, induces that spinning rotor (via a swash plate) to do likewise and displace the rotor’s lift to favor an inclination in the appropriate direction. The anti-torque pedals control the collective pitch of the tail rotor blades and swing the nose left or right in sympathy with the corresponding pedal.

The large collective control stick serves two functions: Raising and lowering it changes the angle of at tack of the main rotor blades by sliding the swash plate up and down on the main mast. The increased or decreased angle of attack allows the chopper to ascend or descend as long as sufficient power is available to drive the rotor.

A twist grip on the end of the collective lever controls the engine rpm and can ensure that proper power is available if the pilot desires. Raising and lowering the collective does also increase/decrease engine power as well but the twist grip provides the fine timing made necessary by non-standard conditions.

I once compared the art of hovering a helicopter to balancing a marble on the top of a beach ball (after having imbibed heavily) — I still stand by that analogy. The combination of having to wed cyclic and collective control movement to the fancy footwork on the anti-torque pedals is the most difficult and important skill necessary to helicopter flying—especially since helicopters are naturally unstable vehicles.

Flying The Rotorway Kit Helicopter

The Rotorway Exec kit helicopter is a bit of another story, though. I expected that a kit helicopter might wind up flying pretty well in light of all the research, and its long, successful history but I was ill prepared for the superb nature of this aircraft.

It literally handles better than several machines in the multi-hundred thousand dollar price range (especially those with two bladed rotor systems). Control forces are moderate but the response is quite snappy — as long as you understand the nuances of the Exec control system.

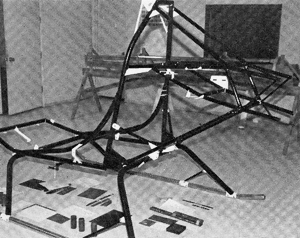

The bare fuselage frame is oxy-acetylene welded and serves as the main structural components of the Exec.

Being the ham handed maniac that I am, I first attempted to manhandle the hell out of the Exec especially since I was expecting the usual mindless excursions that are a part and parcel of light disc loadings and simple two-blade rotor systems. The Exec helicopter has virtually no notice able bad manners.

Slight pressures produce quick responses but hard, excessive, fast movements produce a noticeably “Damped” lag before heading off on a witch hunt. Control response ratios are fairly linear, throttle response is very fast — even for a piston powered chopper and the overall feel is extremely gratifying due to the mild but not overly light stick forces.

Due to the aforementioned habits ingrained by slightly twitchier machines, I had a heck of a time getting used to the Exec’s milder nature. For a little practice, I settled down and played for a while in the 15 to 20 knot gusts that were coming over the top of a nearby building. A few minutes served to dampen my gyrations, so we decided to split.

We headed out over the desert and clipped along at a healthy 90-95 mph after a 1000 – 1100 fpm climb at 65 mph. The gusty conditions were ridden well by the light little Exec while the rotor exhibited the most “stable” handling that I have ever experienced from a non-augmented helicopter.

A combination of effects produced by the smooth but optional elastomeric head and the generous vertical and horizontal stabilizer turned the Exec into a pleasant cruising helicopter that did not require the customary death grip on the cyclic to keep things on an even keel.

We actually cruised for nearly a minute in the semi-rowdy air of that day with hands off the cyclic while the Exec flew itself — I’ve never done that in a piston helicopter before. Naturally; my biggest concerns were the safety of this machine – nice handling is wonderful but won’t save your butt if the rest of the systems don’t support the pilot in an emergency.

Auto-WHAT? Engine Out Proceedures

A few autorotations served as additional proof that Mr. Schramm’s considerable design efforts were not in vain. The power cut is accompanied by a slight pitch up (apparently induced by the horizontal stabilizer), no appreciable yawing from mechanical factors, relatively good rotor energy (despite the light mass inertia of this ship) and excellent response from the control system.

The descent angle (even with this much wind) was not as steep as I would have assumed. The vertical speed seemed pretty consistent at 1200 to 1400 feet per minute and a 60 to 65 mph descent felt pretty sedate. The flare occurs rapidly and quite low (which is to be expected from a machine with this kind of mass inertia—a Bell Jet Ranger, it ain’t).

Still; the energy hung in there for quite a while (allowing for plenty of time to level the skids and prevent a boom strike—one of the autorotation’s most notable hazards). The speed at flare (about 60 mph IAS) was a bit more than I needed, and the short final descent was uneventful.

What followed thereafter, was a real eye opener. One of the cardinal rules that a helicopter pilot should follow is the strict adherence to staying on the better side of their height/ velocity curve – AKA the “dead mans curve”.

In essence, the H/V curve is a relationship that tells a helicopter pilot how much speed and altitude they need during flight (most especially during low level maneuvering or takeoff) to allow for enough time and rotor energy to effect a safe landing before the ground rises up to smack one’s face.

For instance, going real fast at a very low altitude tends to give one very little time to react in the event of a power failure before the machine starts digging up the real estate – not a good place to be.

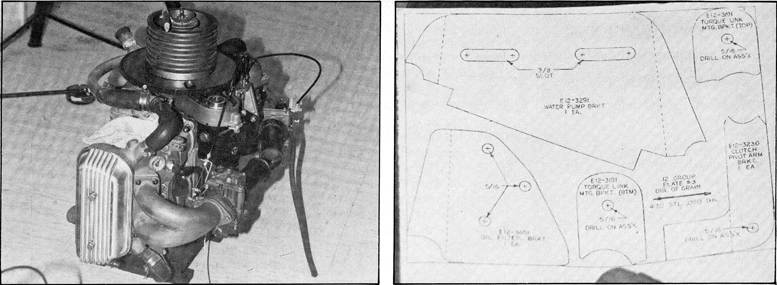

LEFT: The liquid cooled RW 152 power plant used in the Exec—manufactured right at the factory to very tight tolerances. This engine has piled up an impressive record for reliability.

RIGHT: An example of one of the many ways that Rotorway simplifies the building process. “Real life” sized templates can be glued on the appropriate plate and used to cut out the new part.

So … we went out and boogied over the desert at less than 10 feet and 70+ mph—and cut the power! Well … we didn’t die, we didn’t get hurt, and we didn’t even ding the Exec. At the power cut, the Exec did some very uncharacteristic things (as compared to some of their competition).

First, it pitched up slightly (just love that stabilizer and rotor head . . .), and didn’t hit the deck like a ruptured duck—thus giving us just enough time to quickly flare with the cyclic, milk up the collective, and finish shooting a hasty but successful autorotation.

Impressed as I was after this event, I was even more impressed when we did one of these downwind. Another major concern (actually, something of a nightmare . . .) has to do with tail rotor failure.

The loss of this function is a real emergency that can land a pilot in big trouble. The effect of that huge rotor has to be countered by the tail rotor so that the whole machine doesn’t spin in the opposite direction of the rotor — every action has an equal but opposite direction . . . and all that rot.

The Exec minimizes some of those hazards by virtue of its huge vertical stabilizer and the natural streamlining presented by the rest of the fuselage. The combination of these surfaces allows the Exec to “weathervane” when flown at sufficient speed to take advantage of these aerodynamic tendencies.

The slower the speed at which a helicopter will demonstrate an ability to keep “weather vaning” with moderate power usage, the better — in the event of the loss or incapacitation of the tail rotor drive or control system.

With a little power and sufficient forward speed, this ability gives the pilot a better choice of landing areas and eliminates the need for an immediate emergency autorotation. The Exec does well in this department — demonstrating that it can hold its own (with low cruise power—with as little as 25 mph worth of airspeed).

This, I wouldn’t have believed if I hadn’t seen it demonstrated. Mr. Walters made an approach with the tail rotor at zero pitch (no effective thrust) to one of the baseball diamonds at the practice area and seemed quite comfortable with the process at speeds as low as 25 to 30 mph, before backing off the power. Very impressive.

Editor Jim Campbell (up front) gets his picture in the magazine for a change. HI MOM!!!

Test Pilot’s Summary

To those of you with helicopter experience, please excuse my over simplifications and generalizations but I felt that such was necessary due to the overwhelmingly “Fixed- Wing” nature of our readership.

No matter the experience level; it’s not hard to see that I was very impressed with the two seat Rotorway Exec Kit Helicopter. If I suddenly fall into a spare 30,000 smackers, this machine could be very tempting. Even more tempting is the more affordable and sequential availability of the Exec kits.

The helicopter, itself, seems very well supported with factory run training, excellent construction info, regular help from a factory rep during business hours, and outstanding quality of individual components.

I have little doubt that a properly constructed EXEC is an airworthy aircraft. Its use of autogas, efficient powerplant, owner maintained nature and a host of other factors make the Exec a formidable competitor for a Sport Pilot’s mad money.

Even more important, the Exec seems to have the requisite performance and handling necessary to ease a pilot through several of the more common types of heli-hazards. By the way, Rotorway sells a video presentation that describes the Exec in detail — I highly recommend it to even the most casual of interested parties. It’s entertaining, informative and rather nicely done.

If the Rotorway Exec has any serious problems (other than its $30,000 cost — though it’s extremely realistic in terms of today’s market), I don’t know of them. I’m rather amazed at what is possible when someone puts their mind to it — the Rotorway Exec helicopter is quite a testament to the power of the human “will to succeed.”

My congratulations to Mr. Schramm. Personally; I’d love to have one of these machines and a set of floats … what a ball. Now; that sounds like freedom to me.

| ROTORWAY EXEC PERFORMANCE SPECIFICATIONS | |

|---|---|

| Powerplant | RW-152 watercooled four stroke, 152 hp |

| Seats | 2 |

| Gross Weight | 1320 lbs |

| Empty Weight | 830 lbs |

| Equipped Useful Load | 490 lbs |

| Pilot and Passenger Seat Load | 380 lbs |

| Fuel Capacity | 17 gal/110 lbs. 5 gal/aux |

| Rate of Climb | 1200 fpm |

| Hover in Ground Effect | Single place 10,000 ft Two place 7500 ft |

| Hover Out of Ground Effect | Single place 6800 ft Two place 4500 ft |

| Service Ceiling | 12,000 ft |

| Range Maximum Fuel, Optimum Cruise Power | (one person and 5 gal aux) 275 mi/2.75 hrs |

| Range Maximum Fuel, Optimum Cruise Power | (two persons) 201 mi/2.1 hrs |

| Normal Cruise | 95 mph |

| Max Airspeed at Sea Level, Standard Day | 115 mph |

EDITOR: A slightly humerous yet timely and poignant ad taken from a 1987 magazine promoting the Rotorway Exec helicopter video.

SEE IT AT HOME… AND BELIEVE THE THRILL IS BACK!!

AFFORDABLE

The RotorWay Exec is an unbelievable innovation in personal transportation! After all, who would believe this helicopter costs less than a luxury sports car? That its main rotor hub utilizes state-of-the-art elastomeric bearing technology found in helicopters costing $150,000 and up, or that when it comes to performance, safety and styling it meets or beats anything in its class, or that its four cylinder water cooled 152 H.P. power plant runs on auto fuel, not expensive AV gas!?? Can you believe all this? YOU WILL!!!…Once you see it on video!

SEEING IS BELIEVING

As the old saying goes, seeing is believing and not only will you see first hand the evolution of helicopters in general and the evolution of the Exec in particular, but you’ll also take a heart pounding ride with our pilot through picture post card deserts and majestic snow covered mountain peaks.

Then it’s on to breath taking Lake Powell where sculptured red rock towers rise hundreds of feet from the waters edge providing awesome views of the pristine blue water beaches below. Then, with tranquility behind us it’s time for more action packed high speed flying. You won’t believe what this ship can do… until you see it!

UTILITY WITH EXCITEMENT

You’ll see that fun isn’t the only thing the Exec has to offer. Agricultural spray equipment and water floats add utility to the long list of uses this personal helicopter has to offer.

If you’ve ordered one of our information packets in the past you’ll definitely want this video, and our updated information package. You won’t believe what the Scorpion and Exec have evolved into… until you see it!

COST EFFECTIVE OPERATION

Something you CAN believe however, is the fact that the low end of general aviation is dying, if not already dead. FACT! Sales of 2 and 4 place fixed wing aircraft are currently 20% of what they were 10 years ago! Why? Most industry experts say skyrocketing costs are to blame.

That’s hogwash! When you allow for inflation over the past 10 years, the cost really hasn’t increased all that much. So, what’s the reason? Lack of new designs is one thing, but even more so, is the fact that entry level fixed wing aircraft don’t offer much excitement or utility. Think about it.

Is it cost effective to fly the company airplane 200 miles? Not very, and distances longer than that are best traveled on commercial flights. This is especially true now with airline deregulation. Plus the fact that you still need ground transportation going to and from the airport.

In case you haven’t realized it… it’s time for a change. It’s time for the helicopter. You’re ready for excitement and we’ve got it…THE THRILL IS BACK!!! Point to point NOT airport to airport is the most efficient way to fly within a 200 mile radius. Exec totally fulfills the urgent demand for this type of essential transportation.

HELICOPTER VS. SMALL AIRPLANE

Some people will tell you general aviation hasn’t changed in forty years. The truth is they just haven’t been looking in the right direction. Helicopters WILL replace the small airplane! We’ve made this tape to prove it to you, so prepare yourself for some shocking reality!

On top of all this, it isn’t necessary to be IFR rated to fly a helicopter. If weather moves in and your halfway to your destination just land where you run out of sky and safely wait it out. With as little as 2 or 3 acres of land you can park it at your home or office. (Depending on local housing density.)

For you video buffs, this production utilizes the latest in Digital Video Effects and state-of-the-art Ampex Digital Optics combined with an incredibly dynamic soundtrack! The days of two dimensional travel are Over. You can live in a whole new world of affordable three dimensional point to point transportation!

See it…then believe it! THE THRILL IS BACK!!!

i would like to know how much is the kit

https://en.wikipedia.org/wiki/RotorWay

Hi William, please check out our website, http://www.rotorxaircraft.com or give us a call at 602.377.5482. We are just seeing these comments! We just came out with our new model the Phoenix A600. She’s a beauty for sure….we are also running a special pre “Sun’n’Fun”

Hi Kellie, thank you for your contribution and link to your sight. It is great news knowing this fantastic kit helicopter continues evolving.