Helicopters Helicopters For Everyone

ARTICLE DATE: June 1978

Is this the Chopper for Everyman?

Everyone knows that homebuilders are sometimes a rather odd lot. After all, they spend months, sometimes years, in dank garages or basement, laboring away, only to emerge with metal chips in their hair and some sort of flying — hopefully — machine that probably is outperformed by much of the Wichita/Vero Beach/Savannah hardware on the market.

Of course, as often as not, they’ve built something that’s either orders of magnitude cheaper than the commercial equivalent, or perhaps has a combination of features unavailable at any price . . .

There’s an especially weird bunch, though, people that are considered strange even by other homebuilders. These are the builders and flyers of what have come to be called “popular rotorcraft” — various minuscule autogyros and even helicopters that can occasionally be glimpsed whirring like dragonflies above desert dry lakes or thrashing about the perimeters of small airports for hover practice.

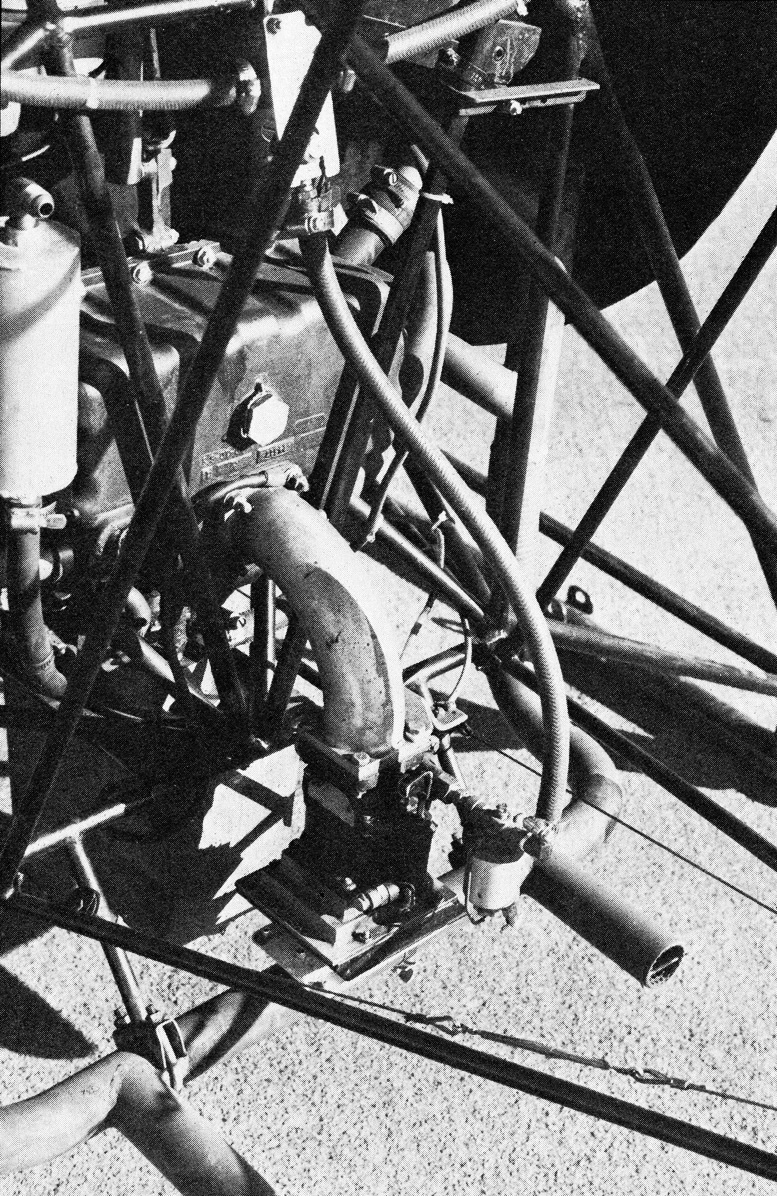

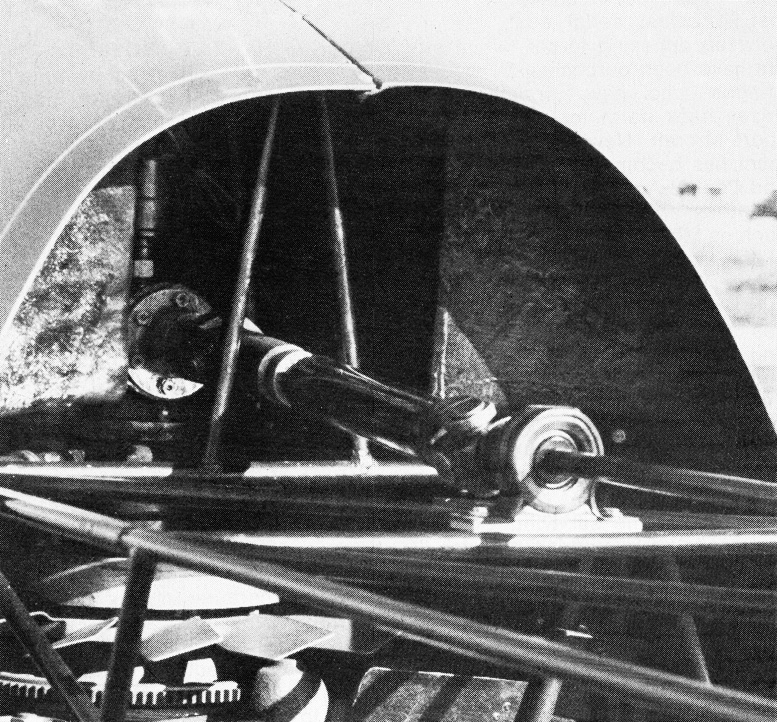

The Lycoming 0-360 was originally designed for horizontal operation; changes required to run vertically include a different oil pickup and a large-diameter induction elbow.

Why are there so few of them? Why do “stiff-wing” homebuilders think that the fling-wing folks are as crazy as their machines? After all, the appeal of one’s own helicopter is immense; here’s an aircraft that’s not just limited to air fields, but one in which you can rise vertically from Your Very Own Back Yard and whizz off in search of adventure — and in a machine you’ve built your very own self.

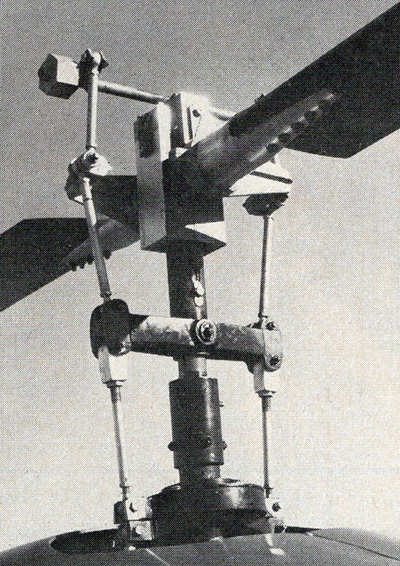

The rotor hub and controls are similar to a scaled-down Bell system.

Let ol’ Fred down the block gloat over his new dune buggy — you’re above all that. Well, there are several reasons why the sky isn’t black with homebuilt helicopters. True, the appeal is there, and the prospect of building something that will allow a person of average means to possess a helicopter — the cheapest commercial ones currently available will half ruin a $100,000 bill—is indeed an attractive one.

Unfortunately, the physical and aerodynamic laws that make commercial helicopters so expensive have never been repealed for the homebuilder, so he or she is up against them just as much as the Bells, Enstroms, Hughes’, and Sikorskys of this world.

Moreover, both helicopters — whether commercial or homebrew — and popular rotorcraft, including autogyros, have less-than-perfect reputations. It’s only recently that the old saws about helicopters have started to be dispelled — things like, “almost impossibly difficult to fly,” . . two hours in the shop for every hour in the air, ” . . lose an engine and you’re dead.”

Unfortunately, the safety record of the pop rotor movement is also poor, due largely to such machines as the Bensen B-8 Gyrocopter. This little autogyro, while not inherently unsafe, was widely advertised in non-aviation publications (e.g. Popular Mechanics), and subsequently built—and flown, and in a number of cases crashed — in great numbers, largely by people with no other aviation background.

Add to this the fact that the Bensen is basically so easy to fly that the neophyte pilot is easily seduced into maneuvers that exceed the limits of its operating envelope, and it’s small wonder that its operating record.has been poor. Even so, there are quite a few folks out there building various wild and wonderful machines.

A few of these are one-of-a-kind attempts and many of this type never leave the ground: either the builder has underestimated the complexity of such a project and abandons it, or engineering difficulties become insurmountable and the project is completed but proves incapable of flight.

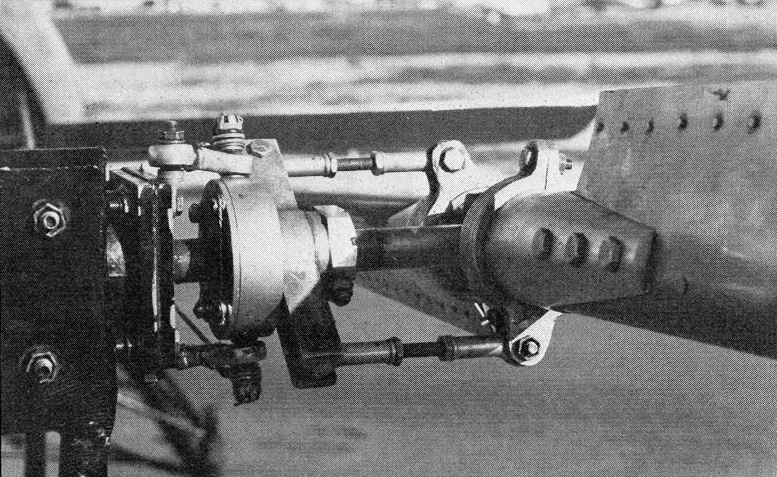

The simple tail rotor control system uses cables and oblique links for pitch change.

Most of the aerodynamicists and engineers who understand the arcana of rotary-wing flight are already working for the major manufacturers. There are a couple of designs, though, that have been available in more or less unchanged form for several years, and that have resulted in the construction of significant numbers of ships.

Hillman Hornet Helicopter

The Bensen, in its various versions, pretty much dominates the autogyro field; in helicopters, the prospective builder has the choice between two aircraft, both coincidentally from the Phoenix, Arizona area and named after arthropods; the Rotorways Scorpion, which will be covered in a future issue, and this month’s candidate, the Hillman Hornet.

Actually, the Hornet has been around for a while, although under a different name. Designed by Harold “Pop” Emigh, who also gave us the Emigh “Trojan” — a little plane looking some- thing like a Culver PQ-14, with odd- looking external wing ribs—it originally appeared as the “Helicom Commuter.”

In fact, for the moment, plans or kits for the Commuter version are still available from Helicom, Emigh’s original company, in Palm Springs, California, Over 100 Commuters have been built since the design first became available in 1966; Doug Hillman, entrepreneur of the company that hopes to market the design in kit form, claims a near-perfect safety record, with no recorded fatalities or serious injuries.

We’ll get down to specifics about the aircraft in a moment; let’s have a look first at the way the Hillman Hornet concept differs from the Commuter, as well as at Hillman’s plans for development of the design. A major difference is that Hillman plans to offer the helicopter in kit form only, rather than as a kit or as plans, as was the case with the Commuter.

Much of the kit, currently priced at $19,500, is pre-assembled, with the 4130 steel lattice tail boom and basic airframe structure tack-welded. Similarly, complex mechanical assemblies such as the main transmission and tail rotor gearbox are preassembled and tested.

The Hillman Hornet Helicopter homebuilder must still complete detail work on the airframe, install and rig all components, assemble the rotor system and its controls, and so on, as well as installing and outfitting the fiberglass cabin enclosure.

According to Hillman, the total of this work is sufficient to qualify under the FAA rule for kit-built aircraft in which at least 51 % of the work must be performed by the builder, even though very little actual fabrication of parts is required.

Another point in which the Hornet differs from the Commuter is the extent to which the factory — and, later, dealers — will control assembly of ships in the field. Currently, Hillman will not sell a Hillman Hornet Helicopter kit to anyone unless certain qualifications are met.

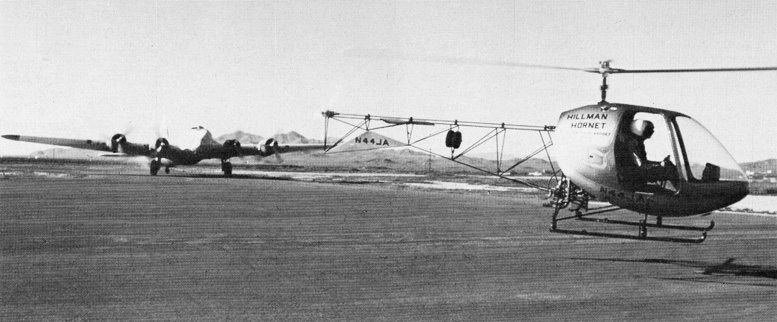

This is what the Hornet will look like when the new smaller tailboom is installed.

These include either an A & P rating or proof that construction will be checked and supervised by an appropriately-rated mechanic, plus proof of helicopter training in a commercial helicopter of equivalent performance and handling, such as a Hughes 300, and membership in the local EAA chapter.

Hillman plans to remain in close contact with the chapter, as well as with the FAA General Aviation District Office having jurisdiction over the area in which the helicopter will be assembled; the FAA inspector who’ll be called in to “buy off” the finished helicopter will receive complete inspection guidelines from Hillman. In fact, at least for the first few units completed, and until a dealer network is set up, Hillman personnel will be sent to inspect each Hornet.

Moreover, they’ll take with them a Chadwick electronic balancing unit to help the Hillman Hornet Helicopter builder get the rotor tracked properly and everything running smoothly, and I imagine that it’s not too far-fetched to assume that at least one of the Hillman inspection team will be a test pilot. All this inspection and control may seem excessive, but I, for one, think it’s a good thing.

The fact remains that any helicopter is a somewhat demanding aircraft, both to build and to fly, and Hillman is very concerned with keeping the Commuter/Hornet’s safety record unsullied. The Hillman Hornet incorporates a number of changes from the original design. The rotor has had a foot added to each blade, and the span of the fixed horizontal stabilizer has been halved.

The most noticeable change has been to the cabin enclosure: where the Commuter has a rather boxy structure made of flat, easy-to-build sheets of aluminum and plexiglass, the Hillman Hornet Helicopter has a sexy fiberglass shell, with a pointy nose and a free-blown plexiglass windshield. (The prototype windshield has a center strip; future units will have none).

Helicom Commuter is a Lycoming-powered helicopter for the homebuilder, designed by the late Harold Emigh.

Doors, either flat or bubble style, will be available as an option on the Hillman Hornet Helicopter. The battery has also been relocated; on the Commuter, it is mounted either on the right skid or in the tailboom, depending on whether the ship will be flown solo or two-place.

In the Hornet, it’s mounted next to the engine, just about on the eg, so it needn’t be moved, thus eliminating both the hassle and the extra weight of the additional power cables. Instead, the little ground-handling wheels are stashed on the right seat for solo work, or clipped to a fitting on the tailboom for dual flights.

At present, the Hillman Hornet Helicopter tailboom itself is the same rather deep structure used on the Commuter. A new tailboom is in the works, though, which is considerably skinnier — Hillman claims it’s stronger than the original.

A plug has already been made for a fiberglass nonstructural skin which will cover the new tailboom, so the helicopter will look quite streamlined—rather like a little Enstrom Shark—rather than having the “mosquito carrying a flashlight bulb” look of the Bell or the Hughes reciprocals.

I had a chance to fly the Hornet with Ed Boyles, Hillman chief pilot and a veteran of thousands of hours in everything from B-17s to turbine-conversion Sikorsky S-55s. Preflight inspection is easy, since everything is readily accessible and close to the ground; it may be a bit more difficult when the new tailboom goes on.

The engine is a regular airplane-style Lycoming 0-320, putting out 150 hp; it’s been modified with a different oil pickup system to run in a vertical position, with an external oil tank changing it into a dry-sump engine for all practical purposes. Primary drive is by shaft to the transmission (no V-belts); there’s a big cooling fan, and temperature was no problem even in the Arizona heat.

The rotor is a conventional two-blade semi-rigid type, with the usual teetering and rocking hinges; unlike the system used by the crosstown competitor, the Scorpion, the Hornet employs a vertically-sliding swashplate for collective control (the Scorpion uses a rocking hub for cyclic control, with a walking beam arrangement activated by a flex cable through the hub for collective).

Cyclic friction at rest is very low, particularly in a fore-and-aft direction. The only oddity is the Hillman Hornet Helicopter antitorque pedals: an open cable circuit is used, and there’s enough slack in the cables to cause quite a “spongy” feel to the pedals.

Hillman plans to change this before kits are shipped—as it is, one forgets it soon, and I found that when I thought I was all out of pedal — hovering in a left crosswind, for example — a good hard shove gained me a bit more. “Left crosswind?!” I hear you helicopter pilots cry—yes, because the Hornet main rotor turns clockwise as seen from above, contrary to most American helicopters but common in Europe.

After the first couple of seconds — during which something “feels wrong” because one’s normal foot position is more or less reversed—one forgets entirely which way the rotor’s turning, even when compensating for large collective movements and power changes. I’m getting ahead of myself, though — we were still preflighting.

Tail rotor drive is by a large-diameter shaft, with sliding splines and U-joints a la Hiller, extending from the transmission to the top of the tail boom, thence via small diameter shaft a la Bell. Rotor control is also reminiscent of Bells, with a small version of the Bell stabilizer bar above the hub, and a little yoke a la – Huey below it. No hydraulic pitch dampers though.

Since this was to be an initial check-out flight, with winds of 25 knots with frequent gusts to 35, Ed got into the left, or pilot’s, seat—again, since the rotor turns “backward,” the helicopter hovers right skid low, so solo is normally from the left, although the ship’s been soloed from both sides.

The Lycoming belched to life quite readily, and the rotor started to swing lazily; Hillman Hornet Helicopter rotor engagement is automatic, and takes about 35 seconds, during which there’s not much to do but sit there, hang on to the cyclic, and watch the oil pressure coming up.

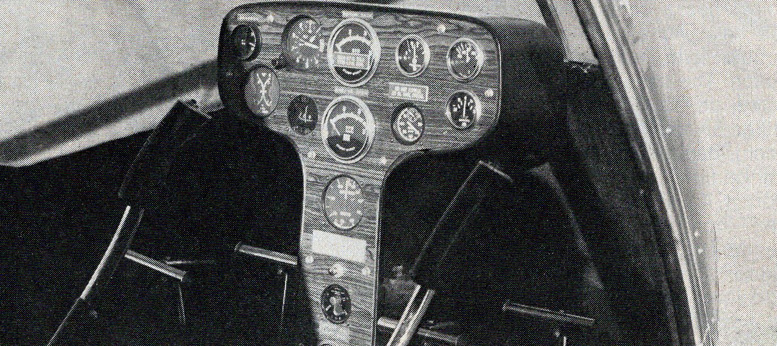

Checking the sprag (overrunning) clutch isn’t quite a matter of “splitting the needles,” since there are separate tachometers for engine and rotor (an economy measure); however, the two instruments are mounted right above one another, and their ranges are set up so that the needles are parallel when the engine and rotor are locked up, so it’s no problem.

In flight, one watches only one tachometer anyway—or better yet, one flies by ear, speaking of which, the cockpit was remarkably quiet—certainly quieter than a 47, a Hughes, or a Brantly (I haven’t flown an Enstrom for a while, so I couldn’t say; they’re reputed to be pretty quiet.) It’s in a hover that the power limitations of little helicopters become obvious—big ones too, for that matter — but this first flight was a cinch.

What with the wind, the thing was into translation just about as soon as we lifted off, and I was able to sit over one spot showing around 25 kt airspeed at only about 23 in. on the manifold pressure gauge (the engine’s restricted to 25 in., although Doug Hillman says the transmission can take more). Throttle correlation is quite good, with not too much twisting required; control feel as a whole is very much like that of the Hughes 300.

There are no irreversible linkages or boosted controls, so there’s some feedback from the rotor system to the cyclic — nothing terribly objectionable, but you’re definitely aware that there are mechanical pieces whirling around and around on the other end of the stick.

We shot a couple of patterns, and the ship handles very pleasantly, but between the wind and the general turbulence it was hard to get a real idea of what was happening, so we decided to try later in the afternoon, when conditions would be calmer.

Doug Hillman got more than he bargained for when he hoped that it would be calmer in the afternoon; it was dead calm, and the temperature was well above 80° F. Moreover, the ship had been at around half fuel during the morning flights; now, the – full 22 gallons were aboard, and what with the prototype’s extra weight here and there, Ed and I were at or near gross.

The tachometer is marked with different rotor rpm figures for solo or dual flight, and it was with some doubt that I wound the revs up to the top of the higher dual range and pulled pitch. No problem, though; the bird lifted off readily, with adequate pedal in reserve.

The two large instruments in the center of the panel are the separate engine (lower) and rotor (upper)-tachometers.

About the first time the low power became evident was when we started a climbout: the transition into forward flight had to be made very gently, and the period between “falling off” the ground cushion and “climbing onto” translational lift seemed quite long.

There was a moderate amount of shaking as we entered translation, but it subsided very rapidly, and once 50 kt or so had been achieved the Hillman Hornet Helicopter climbed quite adequately. Turns and pattern work were entirely normal; again, I was reminded of the little Hughes in handling.

Although I didn’t have the chance to shoot full-on autorotations to a touchdown or even to a power recovery near the ground, I made a couple of descents with the collective bottomed — which takes quite a shove, at least on the prototype — and found nothing untoward.

Disk loading is fairly high, at 3.04 psf, which means the Hillman Hornet Helicopter will tend to maintain revs pretty well at the onset of an autorotation, and inertia for the final pull is also pretty good.

A large-diameter shaft with slip joints and universals drives the small-diameter tail-rotor shaft.

Landings were the other area in which the low power was evident; under the conditions (gross weight, about 3000 ft. density altitude), a decent flare from a moderate rate of descent and about 30 kt required winding on all the throttle available, then easing the collective up quite gingerly.

If we arrived at the hover with the rpm a bit low, it tended to stay that way until “milked up” very cautiously, but once correct rpm had been established it showed no tendency to bleed off. Since the helicopter sits comparatively low to the ground, the “cushion” effect is quite pronounced, and a smooth touchdown takes more of a collective reduction than one might think.

All in all, I came away quite impressed with the little helicopter. It’s cute as hell, which I’m sure will sell quite a few right off the bat, and its handling and response seem quite conventional — “just like a real helicopter.”

Performance isn’t quite up to that claimed by the Robinson R22, with the same engine — in fact, derated a bit — but that’s a production aircraft, embodying some very sophisticated design; this one is, after all, a kit for you to put together in your garage.

Mechanically, it’s as simple as any helicopter I’m acquainted with; I haven’t yet seen either Hillman Hornet Helicopter kit components or an assembly manual, so I can’t honestly say how hard it will be to put one together.

The next move will be up to Doug Hillman and his people. As is so often the case in projects of this type, the big difficulty i s funding. Doug seems quite confident on this score — he’s planning to move into a large factory building at Falcon Field, where he’s now operating out of smaller facilities —and mentions various large prospective investors, both in the USA and abroad.

The latter course may prove to be a fruitful one; the ship is simple enough so that it could be quite attractive to some of the developing countries as a way to start a helicopter industry with a minimum of outlay, and there may well be potential for certificating the design—particularly in a country where they’re still in the process of writing the rules.

If the program can be adequately funded to get a significant number of Hillman Hornet Helicopter kits out the door and into the field, I wouldn’t be surprised if it takes off on its own merits.

At the price of around $20,000, it would make helicoptering accessible to a whole new stratum of aviators, and might make the concept of the “recreational helicopter” less of a pipe dream than it is at present.

In fact, if Air a certain Managing Editor somewhat better, and make some space at the back of the parking lot available, I’d certainly be tempted to build one to commute in — I think the industrial zone we’re in is zoned for private-use helipads . . .

Old and new — the Hornet hovers past a taxiing B-17 Flying Fortress used for firefighting.

Be the first to comment on "Green Hornet – Hillman Hornet Helicopter"