McDonnell Douglas MDX Helicopter Development

ARTICLE DATE: Furuary 1990

Chancey as it is these days to just develop a new commercial helicopter, MDHC has gone one step further, applying quite radical procedures in design and production. It has apparently paid off.

“THE CENTRAL POINT to make about the MDX is that it started with a clean sheet of paper. The philosophy was simple: build it right, make it affordable, and the market will speak for itself. We think the market has spoken.”

McDonnell Douglas Helicopter Co.’s (MDHC’s) Bob Buffum talks confidently about the program he heads up. He gazes across the Mesa, Ariz., desert from the Spanish “hacienda,” where his unique 150-man MDX development team is based.

The facility is near, but not within the MDHC compound. His team has been tasked to develop the first all-new helicopter solely for the civil market in at least a decade. In addition to not having a tail rotor, the MDX is unique for many reasons.

“Up to now, the theme has been to build a helicopter, and then support it with parts,” says Buffum. “Costs to operators started with great uncertainties, and only experience revealed the true, expensive story.”

“What’s changed is that now we can make those ownership costs predictable.” Thus, the MDX may demonstrate that rotorcraft can achieve the kind of economic maturity that its fixed-wing brethren have long enjoyed.

Operator Input

MDHC may be the MDX manufacturer, but the aircraft is also the product of thorough scrutiny by operators. The design for this twin-engine eight-seat machine arose from a series of so-called “blue team” requirements sessions.

Taking the initial responses from 177 operators worldwide, MDHC organized a 15-man team of users who were to help make design and performance decisions. For example, the team took a close look at a single-engine alternative and examined various seating arrangements.

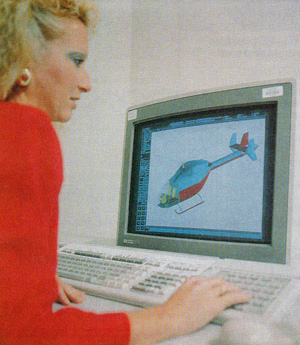

Using the Unigraphics II 3D design package, designers can generate and modify the MDX design. This computer system virtually eliminates the need for pencils.

The blue team has remained with the project, offering critiques throughout the design process. In fact, team members participated last October in a “preliminary design review,” a procedure borrowed from military practice.

They examined what is close to being the final configuration to how closely it fulfills the original set of operator needs. The design “freeze” is slated for November, at which point “build to” packages (sets of specification) will be released to MDX suppliers.

With hindsight, this team approach appears to have been an obvious procedure, yet it is not a common one. Says Chuck Johnson, executive vice president of ERA Aviation Inc., “This was the first time in my 20 years in the industry it happened.”

Once the blue team’s input was incorporated, an in-house “red team” scrutinized the design from a company point of view. The project first had to be “sold” to McDonnell Douglas at the corporate level, perhaps the biggest selling job of the entire project.

“Believe me, launching a new helicopter in today’s environment only sounded like a good idea if it could be proven to be one,” says Buffum. “MDX had to meet many tests before the go-ahead was received.”

User interest

The tests apparently paid off At the 1989 Heli-Expo show in New Orleans, MDHC executives accepted a staggering 150 certificates of interest, each requiring $10,000 from the buyers.

“We were looking for 50,” recalls L. Clark Wirthlin, head of MDX marketing, “and then 150 by mid-1989. We passed both those targets, and it was all by word of mouth and what appeared in the trade press. Imagine what will happen when we start marketing hard.” Wirthlin hopes for a steady escalation of sales options, with sales to eventually reach some 800 MDXs.

That, at this stage, is MDHC’s target; it represents about 30% of the projected light-twin helicopter market over the next decade. At the end of 1989, there were about 230 certificates of interest on file, a good 60% of them from U.S. operators, with Canada, Europe, South America, and the Asia-Pacific region following in order.

Although the list is still confidential, Wirthlin believes “about 20%” of the options are speculative. The rest are solid: well-established operators, dealer networks, aeromedical services, and “some offshore” companies. Corporate sales looked particularly strong.

Wirthlin believes the blue-team approach contributed to such buyer interest. Potential customers who took part in the MDX project, he theorizes, feel they “have a share” in its fortunes.

MDX has been assigned a firm fixed price of $1.7 million in ’88 dollars. This allows upward adjustments only for annual inflation before first aircraft come off the assembly line in 1993.

The aircraft was developed to have a fixed direct operating cost (DOC) as well: $200 per hour. For that, an operator will get a plain-vanilla MDX, with basic VFR flight instrumentation (but not avionics), seats, a finished interior, and pilot and maintenance training plus other support.

Suppliers/partners

MDHC regards the MDX suppliers, particularly those handling the major sub components, as equity partners. This, according to Buffum, ensures an all-round commitment to the aircraft’s quality and the program’s success.

“We will not be jumping around from vendor to vendor; it’s far better to work with the same people,” he explains. “If the subcontractors need our help, then we can swing the MDHC resources behind them. We can ensure the quality.”

“They, in turn, will be making significant business commitments, which lock them into continuous improvements in their processes,” Buffum adds. “They are risk-sharing partners with a big stake in the program.”

There are now four such partners on the MDX project: Hawker de Havilland of Australia, Kawasaki Heavy Industries of Japan, Pratt & Whitney of Canada, and Turbomeca of France. Agreements with Hawker and Kawasaki were finalized just after the MDX launch decision was announced.

Their participation was vital to controlling costs, because one of the biggest stumbling blocks a company like MDHC must overcome is that of high over-head—from, say, military products like the AH-64 Apache—spilling over into the MDX program.

MDHC employees try out MDX seating arrangements in this plywood mockup. Here they slide in a makeshift litter to test the helicopter’s EMS configuration. The mockup also shows the extensive visibility offered from the MDX cockpit.

MDHC strategically sought vendors without such overhead situations, and decided to “make” as little of MDX as possible. It restricted the activity at Mesa primarily to assembly.

Production expenses in both Japan and Australia are lower than in the United States, and MDHC moved early to sign exchange-rate guarantees to ensure a lower price rate. All parts will be paid for in dollars.

MDHC CAD/CAE.(computer aided design/engineering) software is shared with suppliers, as is a newly developed three-dimensional design package called Unigraphics II.

This package uses computers to generate design drawings of the project, eliminating the need for manual drawings. But more than that, Unigraphics II also provides instructions to the computers used during the manufacturing process.

Further deals are still in the works. Who, for example, will manufacture MDX blades? By scouring the world for worthy suppliers and then sharing with them the project’s success, MDHC has secured some impressive performance guarantees.

Kawasaki, for example, pledged to produce a lightweight transmission that will run 5,000 hours average time between removals. MDHC is also seeking unlimited warranties on some components, and succeeding—though details are not yet available.

At Hawker de Havilland, three years of negotiations preceded the Australian firm’s decision to accept the task of developing and producing MDX fuselages. The decision represents the company’s largest investment in an aerospace project.

Keeping it simple

Technical risk, on the other hand, is being kept low. A lot of MDX will be good old-fashioned aluminum. Only a limited number of parts will be made of composites.

The reason? There are still too many questions about composite properties for the costs to be pinned down, says Bufifiim. Composites “are a bear” when they are joined to metal or fashioned into compound curves, he adds. And not enough is known about field repair.

“We wanted to avoid all those types of problems and not pass anything like that on to the customer base. I guess the decision was to ‘keep it simple, stupid.'” The choice of two engines, either the Pratt & Whitney Canada PW206A or the Turbomeca TM 319-2, is a competitive element aimed at customer assurance.

The engines are essentially similar in performance: both are rated at 603 shp takeoff power. Direct operating costs are also similar, though the French engine will post better specific fuel consumption (SFC) because of its electronic fuel control.

But more than costs and fuel efficiency, according to Buffum, “the cry we heard over and over was ‘give us more installed power’.” MDX is not playing one engine off against another—exactly. But, considering the engine troubles that have plagued some helicopters, offering a powerplant choice seemed prudent.

The PW206A will power the first 100 MDXs. The reason: an earlier selection process resulted in choosing between the Pratt powerplant and an Allison 250-C30. Pratt won that competition; the Allison was too heavy. Then the Turbomeca folks decided they wanted to be in on the MDX. Certification of the 319-powered MDX will begin in early ’93.

Whichever engine is chosen, the customer will be given something everyone in the blue team wanted: the ability to climb away one-engine-out in ground effect at max takeoff weight and at 3,000 feet density altitude (DA).

The DA figure was originally 4,000 feet, but the decision to install particle separators as standard equipment meant a small compromise in performance. Installing Centricep particle separators to the aircraft structure allowed MDHC engineers to eliminate a ram air intake for MDX.

The result is a smoother design, less duct work, and therefore less cost. The savings here were balanced against the performance issues. Cost won because, according to Buffum, “3,000 feet is probably as far as we have to go. This is not a military special forces helicopter.”

Shedding pounds

Buffum’s MDX team fought weight with the zeal of champion jockeys. By late 1988, they “sweated out” much of the design weight. They also reduced fuel capacity by 200 pounds (91 kg), but MDX will still offer a 300-to-350-nm range, says Buffum. The MDX will hold 146 U.S. gallons (550 lt).

more accurate.

“We found there was no need to add the extra 30 or 45 minutes for reserves,” he explains. “Helicopter operators tend not to regard the reserves figure as critical. They will plan to have reserves within the normal still-air range. Quoting the additional range did not turn people on, so we took it out.”

This MDX rendering (1990) reflects the joint design work by MDHC and helicopter operators.

The reduced weight is aimed at another goal: a design gross weight of 5,400 pounds (2,450 kg) and an empty weight of 2,520 pounds (1,140 kg). The MDX’s gross weight with an external load is 6,030 pounds (2,735 kg).

MDHC engineers also pared down weight by taking a gear from the NOTAR fan transmission. The fan must now rotate in the counterclockwise direction; however, the engineers claim this creates no problem. “We’re OK on weight,” Buffum affirms. “We’re going to make the guarantees.”

Regarding another operational matter, Buffum said the MDX will meet some Category A requirements. It will have the necessary engine-breakup isolation and independent fuel system to meet the airworthiness standards. But whether to certify MDX as a full Cat A machine must await a future decision.

“You do Cat A, and you add half a million in nonrecurring testing costs,” says Buffum. “We’ll have to see what the market says.” As for noise, MDX should be an extremely “good neighbor,” since it is minus a noisy tail rotor.

Although 3D software negated the need for a full-scale engineering mockup, MDX designers have constructed a wooden cabin mockup, to help create the MDX display for this year’s Heli-Expo, held in Dallas, Texas. This writer’s first impression was that MDX pilots will enjoy excellent—perhaps unmatched—visibility.

Shaving down the MDX’s nose shape, engineers took out 14 inches (35 cm) of plexiglass to save weight. However, this had little effect on the cockpit’s airy feel or aircraft’s external appearance.

Ergonomics were obviously applied to the MDX’s unique cyclic- and collective-control designs. Also, the interior has an uninterrupted flat floor running from cockpit to aft cabin, allowing easy installation of,say, EMS stretchers. Also for EMS customers, the MDX has a rear cabin door.

Five avionics packages will be offered to MDX buyers, ranging from simple VFR to dual-pilot IFR. Unequipped MDXs will start off with a series of liquid crystal displays (LCDs) of flight systems information, check lists, and instrumentation.

Installing an autopilot could be tricky. The, MDX is said to be so stable—thanks mainly to its “flexbeam” rotor and the NOTAR (no tail rotor) design—that it will not use stability augmentation. Controls will be direct-linked to the actuators. Adding autopilot servos would present more problems than it would be worth at this stage of development, designers believe.

In many ways, MDX may well be labeled a radical new design—but obviously not so radical as to scare away customers.

Hughes 500 Helicopter

Minor improvements for the Model 500 They may be subtle to some people, but they still make a difference. McDonnell Douglas Helicopter Co. (MDHC) has made several improvements to its 500E and 530F helicopters.

All of the improvements were first fixed onto aircraft No. 384, shown here, which was slated for delivery to Masling Rotor Wing Pty. Ltd., a MDHC distributor based at Cootamundra, New South Wales, Australia.

Perhaps most noticeable is removal of the metal rim that wrapped around the aircraft’s nose from the tip. Now, a large, clear piece of plexiglass is installed; it is said to trim away a pound or two, and provide some 30% more visibility.

Other improvements include the following:

Removing the “surf board” on the transmission cowling, saving five pounds (2.3 kg);

Installing a new, lighter fiberglass material in the interior, shaving off 40 pounds (18 kg); and

Replacing fiberglass with more durable metal on the fairing for the landing-gear struts.

Keith Windham how much would the mdhc fusage body helicptor body cost just the body only email me

You’d have to contact the manufacturer direct…

I think the mdhc body look good McDonald’s helicptor body looks great Keith Windham