Kit Built Angel Helicopter

ARTICLE DATE: February 1997

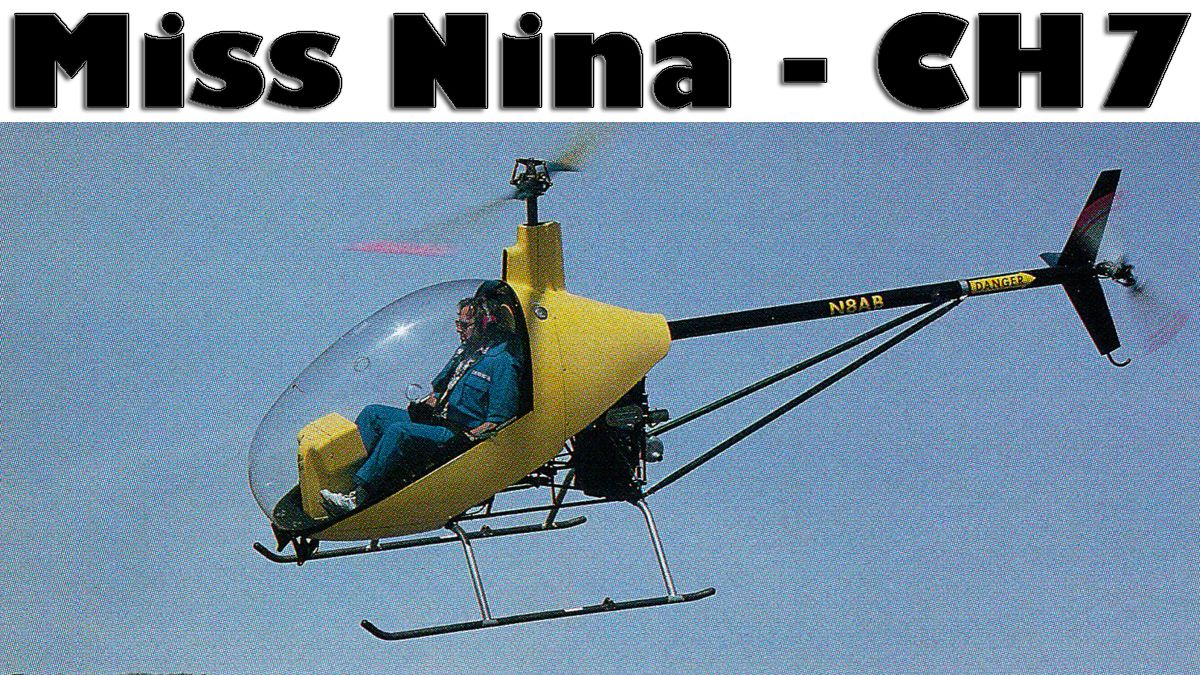

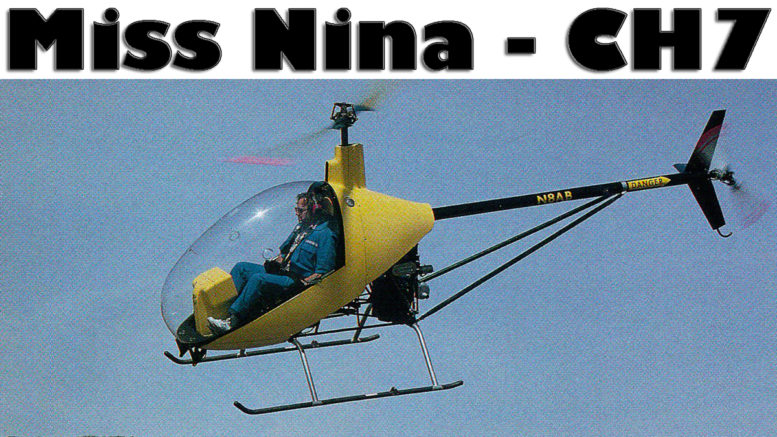

This pilot takes it to the bank in his Italian single-seater

“In the 1950s, when I was a kid in Hawaii, my dad was a warrant officer in the Navy. I saw an Army Bell H-13 helicopter land on the beach, and that turned me on to aviation,” says Glenn Ryerson of Stroudsburg, Pennsylvania.

“Also watching Sky King and Whirly Birds television programs added fuel to the fire, so while in high school I worked as a lineboy at the Mt. Pocono Airport (now East Stroudsburg Airport) after school and on the weekends for more than two years. This led to obtaining a private ticket during the same period.”

Ryerson, now 46, also acquired his glider rating in Germany while serving as an Army aerial photographer, and later he became interested in hot air balloons through the efforts of friend and balloonist Jim Naiz- by Ryerson then earned a commercial hot air balloon rating and purchased an 88,000-cubic-foot Head AX8 balloon, which he flew for 10 years.

Designer Augusto Cicare (right) and Elisport President Pier Luigi Barbero show off the CH-7 prototype.

He also made friends with Bob Strenz, a Robinson R-22 helicopter dealer at East Stroudsburg, became a helicopter student pilot, and added a rotary wing (helicopter) rating in 1990. “Strenz later showed me a brochure on the little single-seat Italian kitbuilt CH-7 Angel helicopter,” Ryerson says, “and we decided to take a trip over to the Elisport factory in Turin, Italy, in November, 1992.”

“There we met Augusto Cicare, the Angel designer, Elisport President Pier Luigi Barbero, and his three sons, who without further ado, generously permitted me to fly the third prototype Angel. I now felt that flying fixed-wing aircraft was rather boring compared to helicopters, and once I was at the controls of the Angel, I got real serious about it.”

“But I wasn’t keen on obtaining an early kit as I heard that there is a learning period in developing and producing kits. This resulted in my purchasing the 60th kit in July, 1994, after sale of my balloon and mortgaging my house to pay the $33,000 price.”

Meet an Angel

Before we go farther, here is some background on the Angel helicopter. It is officially designated CH-7, or Cicare Helicopter 7, actually the seventh single-seat helicopter design by Italian born Argentina citizen Cicare of Buenos Aires. He made his first homebuilt helicopter, a coaxial-rotor-configured craft, in 1955 at age 18.

Lack of materials, parts and funds required Cicare to scrounge and innovate, even to building his own power plant. He also taught himself to fly, and although some of his projects were overbuilt due to lack of proper materials, each subsequent CH model was an improvement.

For a short period, the Argentine Air Force funded and test flew the CH-6 with a thought of using such models for training and agricultural purposes. Dennis Fetters’ present Mini 500, being produced in kit form by his Revolution Helicopter Corporation, is a developed version of the Cicare CH-6.

Cicare’s association with Revolution Helicopter was terminated, and since 1992, he has provided licensing rights for his newer CH-7 Angel to Elisport and its Aerosport distributorship, which also handles the Avid Aircraft series of kits in Italy.

Cicare is currently tweaking a new twin-engine, two-place helicopter in Argentina, and he is said to be marketing a helicopter simulator, designated SVH-3, in South America. Regarding the CH-7, Ryerson believes that Cicare has pretty much accomplished his goals, which were to develop a small, affordable, quick-to-assemble kit helicopter.

The Mechanics

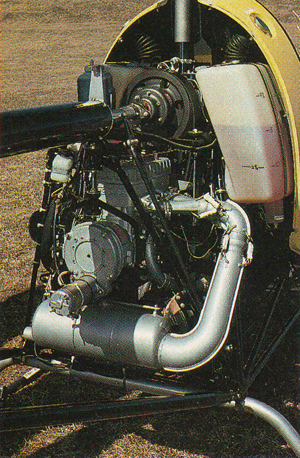

Quick removal of the engine fairing reveals the CH-7’s Rotax 582 two- stroke, liquid-cooled engine.

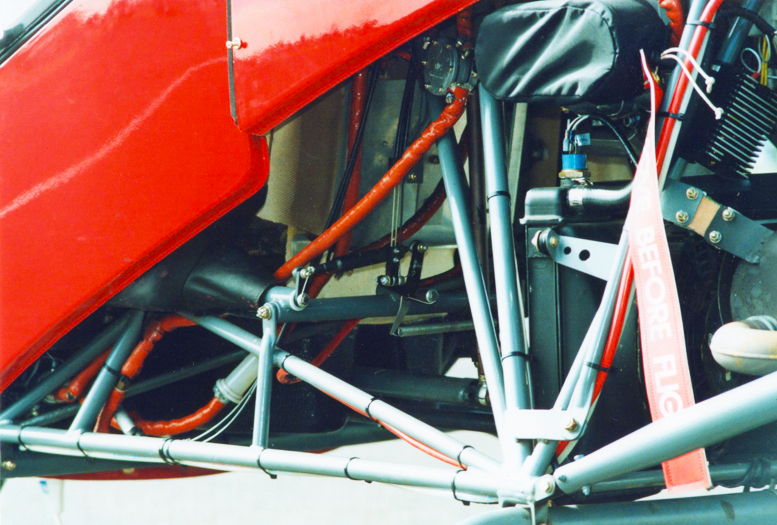

The Angel is a conventionally configured helicopter with a main and anti-torque tail rotors. The airframe has a welded 4130 chromoly steel structure carrying the 64-hp Rotax 582 engine, rotor mast, transmission, tail rotor and the skid landing gear steel down tubes. Longitudinal skids are aluminum of 76- inch length with a 62-inch tread.

The steel airframe incorporates a 32-psi tube pressurization system monitored by a cockpit gauge to keep tabs on the frame’s integrity. This is a safety-related system not usually found in small helicopters.

Main rotor blades are composite and formed by winding strands of pencil-thickness filaments length wise around foam cores. Originally, the CH-7 helicopter had symmetrical blades, but Elisport has since gone to an asymmetrical profile with a 6° twist that are said to have improved performance. Blades are left unpainted, except for the 3.3-pound weighted tips, to enable a see-through inspection. Rotor diameter has also been increased from 19 to 20 feet.

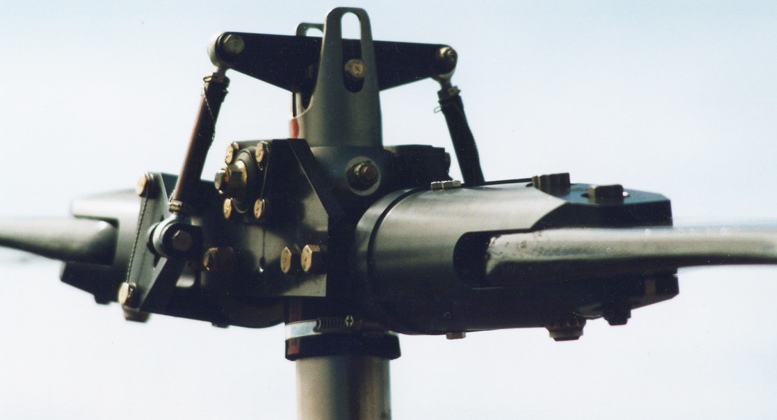

Cicare also developed a simplified rotor system with fewer parts than is normal. It features a teeter-type coning rotor with a semi-rigid head. The rotor head itself is steel, but the bearing head housing is said to be aluminum.

Lead-lag adjustment to the blades is through eccentric bushings in 0.025-inch increments. The head, which contains elastomeric bushings for teetering, moves through 12° positive pitch at full up collective, down to 2° negative for autorotation. Elisport provides a fully assembled head in the kit.

Preparing for a flight to the bank, Ryerson refuels Miss Nina in his workshop/garage – hangar.

Ryerson comments, “Cicare has eliminated the oscillating swash plate found in numerous helicopters, employing instead a stationary swashplate under the transmission, thus eliminating a lot of parts.”

A five-belt reduction drive was initially used, but the system now features a single five-groove, 2-inch-wide belt developed for the Angel by Goodyear. Another method of cost-cutting and simplification is the supply of what Ryerson calls giant rubber bands (cut from auto tire inner tubes) as the return springs on the clutch system. Clutch actuation is through a lever on the right side of the cockpit.

The tail boom is a 4-inch-diameter aluminum tube that carries a 1.25-inch-diameter drive tube for the tail rotor, with tail rotor pitch controlled through push-pull tubes. A clutch engage cable is the sole cable in the helicopter.

Cicare also went out of his way to provide a well supported tail rotor drive. It is bolstered by two mid way bearings, with the only unsupported area being the 39 inches between the last bearing and the teeter-type tail rotor.

Its blades are all metal, contain a spar, have a NACA 63014 symmetrical airfoil, and an 8° twist. Tail rotor diameter is 40 inches, chord 3.8 inches. The vertical stabilizer has a height of 40 inches, and the horizontal stab spans 16.25 inches.

Design and construction technique of the main rotor blades and cockpit are credited to Marcello Gandini. He has an international design consulting organization in Italy that has blueprinted numerous Italian, German and French sports cars, trucks and custom vehicles for the manufacturers. Gandini is also aviation oriented and has been involved with motor gliders, but the Angel is his first rotary-wing project.

The cockpit is nicely enclosed with a wide-vision bubble canopy that swings up and pivots down slightly for main rotor clearance. Inside, the cockpit has a width of 29.75 inches, and Ryerson reports that a 6 foot 4 inch pilot can be seated without his head striking the canopy. The leather covered seat is not adjustable and is formed with fiberglass over a metal frame that is integral with the airframe. A small bag of tools can be carried under the seat.

Building One

After getting his kit in mid-’94, Ryerson assembled it in a former RANS dealer hangar at East Stroudsburg in about 200 hours over a three-month period “with some physical and mental support from friends Cliff Haley and Emil Rolando,” he says, adding that “A major difficulty was the final balancing of the rotor system. I had never even built models as a kid, and since this was a delicate procedure, I had Ron Froberg, a helicopter pilot and A&P mechanic, check my work. Then a rep from the Chadwick Helmuth Company double checked it.”

Ryerson owns and operates a seasonal fast food and ice cream business in nearby Scotrun, and since he started work on the Angel during his busy season, aircraft activities suffered. “I could only devote 2 hours a day to the helicopter, and sometimes an hour at a time,” he comments.

This first-time builder completed his project on October 13, 1994, at which time the FAA gave him a temporary airworthiness certificate. The first flight was delayed until March 10, 1995, and it took until October 20 that year for him to fly off the FAA-required 40 hours and apply for the permanent airworthiness certificate.

Using the electric dolly that he built, Ryerson escorts his CH- 7 from home to heliport.

Ryerson thus became the first builder to complete and license a CH-7 Angel in the U.S. The kit comes without an engine, and the purchaser can opt not to include the fiberglass cockpit area enclosure and instruments. Ryerson recommends that a builder purchase his instruments in the U.S. for cost savings.

Ryerson has equipped his cockpit with a fighter type Infinity Aero stick grip with a starter switch on top. “If you lose the engine and are in autorotation, its nice to have the starter switch at your finger tip to attempt a restart,” he says. A voltmeter and water pressure gauge have been added to the panel. The location of the fuel gauges behind the pilot is not to Ryerson’s liking, so he plans to install a low fuel warning light, as well as an engine two-stroke oil warning system.

Elisport originally included an electronic flight recorder as standard in the kit, but according to Ryerson, it became an option and was later eliminated. “Because of its complexity, you have to be a computer whiz to install it,” he said.

The Cost

Ryerson’s original $32,000 price for his Angel has now reached $41,000, and he is not finished with fitting out Miss Nina. As funds warrant, he plans to add a radio and compass, as well as a hard hat for himself. Ryerson is the U.S. dealer for Elisport but notes that he has not sold any.

The CH-7 kit price is a problem, he says, compared to the American-made Revolution Helicopter Mini 500. The Mini 500 kit price has recently been lowered to $26,500 including a Rotax 582 engine and instruments. The CH-7 kit price also does not include shipping from Italy and U.S. customs fees.

Living with an Angel

Miss Nina was named after Ryerson’s cat, but the name is also the right size to place in the small avail able area. The helicopter is kept at home in a two-car garage “…as a helicopter should be,” Ryerson adds. However, his 8.5-acre property is covered with trees, and being an environmentalist, he has not cleared a helipad area.

Fortunately, about a half mile down the rural road there is a farm with aviation-oriented owners who are permitting him to use an area. To move the helicopter between his garage and the operating site, Ryerson designed a steerable dolly that incorporates the battery pack from an electric wheelchair. It is also fitted with a tall pole carrying flashing red lights to warn approaching cars.

Flying to the Bank

Here are some of Glenn Ryerson’s thoughts about “flying with an Angel,” as he describes it. There are two categories of aviation lovers, he says: people with free time but without enough money to own an aircraft; and the second group, those who own an air craft, but because of a busy schedule, do not have enough time to use it.

“Wanting to be self-employed,” he says, “I chose the ice cream business with the idea of working hard in the summers and then playing hard in the off season. I am pressed for free time in warm weather, but I rationalize a flight by using Miss Nina to make my business’s bank deposits. In fact, I seem to allow my deposits to pile up, just to deepen my excuse to fly to the bank. The flight also requires a 45-minute earlier start than if I were to drive to the bank.”

After walking to my garage/hangar and checking all of Miss Nina’s fluid levels, I secure her to the electric dolly for the walk down the road to Carl and Verdin Rustine’s farm: my heliport.

“There I remove the dolly and complete my pre flight. It takes about 20 minutes from leaving the garage to strapping myself into the four-point hitch. The pilot’s operating handbook says one should engage the main rotor as soon as practical to eliminate a flat wear spot in the inner side of the belt, which I do after starting the Rotax and ironing out any kinks.

The Angel’s engage system/clutch is similar to the clutch on the Hughes/Schweizer 269 and 300, although theirs has an electrically engaged clutch, and mine is mechanically actuated by cable. This being the case, one must engage the clutch slowly by bumping it into the fully engaged position so as not to stall the engine while matching speeds.

“After full engagement, I warm Nina up to 50°C for about 2 minutes before bringing her up to 100% and then check both mags and the free-wheeling clutch. During the initial liftoff, you must remember to decrease the throttle when raising the collective to keep the rotor/engine from over speeding. I always hover a short time with the tail in the sun, when wind conditions permit, and often do a hover rotation or two as a final check.”

“Hovering the CH-7 is surprisingly less demanding than the R-22. Initially, I was somewhat concerned, as it seemed that because of the light weight of the Angel (451 pounds), the CH-7 should be more squirrelly than the 950-pound R-22.1 was totally wrong.”

“I am a firm believer in the height/velocity-dead-man’s-curve, so takeoffs are in an airplane-type run when possible. After pickup, I hover off to the down wind end of the 15-acre field, and before my takeoff, I conduct checks of all gauges in the green, check fuel, canopy locked, check for traffic, say a few words to myself, and off I go.”

“I’m not a lover of two-stroke engines in general, and even more so in a helicopter. With a two-stroke engine, one must keep the revs up to the top of the green during low-load conditions to maintain airspeed over the blades, particular throughout run-up and descents.”

“There fore, all my flights are not only VFR, but also IFF (I follow fields) in case the Rotax warning disclosed in the engine operator’s manual comes true. The manual starts out with the word DANGER in bold print and that this engine, by its design, is subject to sudden stoppage! Engine stoppage can result in crash landings. Such landings can lead to bodily injury, or death.” EDITOR: See “Mini 500 helicopter”.

“The manual goes on to other warnings relative to operating locations, airspeed, altitude and other circumstances facing an aircraft equipped with a two-stroke Rotax, so I go out of my way to always fly VFR-IFF. After clearing the ground toward the end of the field, I circle my takeoff area a couple of times to gain altitude before heading over the trees. I climb to about 700 feet before moving toward a string of fields that lead to Interstate 80”.

“The helicopter climbs effortlessly at 700 fpm at 60 mph. At about 1000 feet agl, I level off, at which time I am turning east and fol lowing the Interstate. The area alongside makes a perfect landing zone in an emergency. My parkway exit is the next set of old farm fields that lead to the rural branch of the Palmerton Bank at Sciota”.

“I have been cruising at about 85 mph for close to 10 minutes, but now it’s time for descent, so I swoop down to a four-lane 1-80 feeder road and toward the bank. The Rotax revs must be kept up close to its 6300 rpm red-line during descent, because exhaust gas temperature (EGT) rises due to the lean fuel/air mixture required in a low-power situation”.

“This becomes even more noticeable in a left hand descent where even less power is needed. Descending takes the greater majority of load off the engine because the main rotor begins to gain some of its energy from the relative wind ascending through the blades. Under these low-load/high-rpm conditions, EGT rises in all two-stroke engines, and if not dealt with it can cause immediate piston seizures. If I see the EGT too close to the red-line, I add a little throttle and pull more pitch”.

“This may cause me to overshoot my intended grass field touchdown spot behind the bank, so I just go around once again and descend at a lower rate. One of the things I love about the Angel is the visibility the fighter-like canopy offers”.

Ryerson plans to augment basic instruments with a compass and a radio.

“When I am close to my landing spot, I add pitch with the collective to slow the descent. The Angel’s mechanical throttle and collective correlator seem to roll in the almost perfect amount of throttle just by lifting the collective. A small amount of adjustment either way is needed to keep the rotor rpm at the top of the green”.

“I finish my final at 50-75 feet in a deep descent and settle into a 3-foot hover for the landing. Normal rate of descent is 300-500 fpm, with an approach speed of 60 mph. Cool-down takes 90 seconds to 2 minutes in two stages: first, at 75% engine rpm, then at idle. Shutdown is a three-count procedure: mags off, master off and clutch lever disengaged”.

“The distance between my home field and the bank is under 10 miles and roughly a 10-minute hop, but fun all the way. However, my 10 gallons of fuel provides a cruise range of 175 miles with a 20-minute reserve and 4-gph fuel consumption”.

“I must admit that the first time I land ed at the bank, during my walk around the side of the building to the front door, I had a perma-grin on my face. I had labored some 44 years to one day own a helicopter and was realizing at the moment that a boyhood dream was not only coming true, but I was in the middle of it. I was able to purchase a tiny helicopter, assemble and fit it in between the cars in my garage. I had moved from a 4x4x11-foot box of parts to having what I think is a beautiful, sexy dirt bike of the sky. Assembling her was not like putting a Revel model together, nor was it brain surgery. It may very well have been the most challenging but rewarding experience I will encounter in my lifetime”.

Mini 500’s in 1997

Glenn Brinker’s Mini 500 – As a first-time builder, I can’t express the joy and satisfaction of experiencing the realization of my dream of completing this ship. It has been an exercise in enhancing my self-esteem, and I have a nice helicopter to boot! After 500 hours of my own work and 300 hours of work completed by friends, we pulled the helicopter out of the garage. Everyone who has seen the project has marveled at the quality of the kit and the assembly manual. Also, the factory support was prompt and valuable.

Be the first to comment on "Miss Nina Is An Angel"