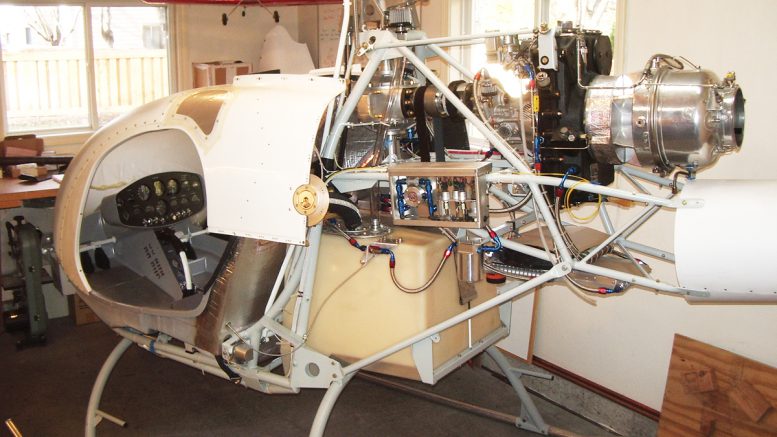

Rotorway Jet Exec Turbine Powered Kit Helicopter

Developed by David Domanske in association with Don Hillberg, the JetExec is a simple but very smart modification that would bring the Rotorway Exec 90 kit helicopter into the modern age.

VIDEO: Super smooth flight – JetExec Flying a circuit

JetExec Owners Information

JetExec Specific Handling

Pilot experiences, thoughts & recommendations.

Practice Autos – Power Recovery to Hover

A practice autorotation in a JetExec is performed essentially the same as for a standard Exec but in the recovery, I feel particular attention needs to be given to restoring engine RPM and joining the needles smoothly. This should happen during the flare and BEFORE the RRPM begins to fall below 100%.

Why I think it’s really important is because of a possible over-torque situation that could occur on the drive train and rotor system. If the throttle is opened fast to full, the turbine will spool up very quickly from the 90% to 100%. The governor may even overshoot the 100% very slightly.

If the RRPM is at 100%, that should be fine but if you have let the RRPM drop to anything less than 100% and you wack open the throttle, a momentary over-torque situation could result as the sprag unit locks up and lets the mighty little turbine pull everything backup to 100% with every bit of up to 160 shaft H.P.

Remember, the governor controls your power to try and maintain or achieve the set RPM. It does not hesitate to fully open the fuel flow to maximum, even if just 1% below the selected RPM setting.

Fly Safe, Roger.

Rotor Spool-up

After engine start it is very important to follow the recommended instructions for the rotor spool-up to minimise wear on the C-clutch and prevent possible damage. The clutch has locking pins that will throw out at around 80% RPM. This should of course only occur after the clutch is fully engaged with no differential RPM.

If you use too high an RPM to spool up, you may damage the pins or even destroy the C-clutch. Also pay attention to lowering the collective to 0º pitch at the right time and consider also applying some left pedal to set the TR to 0º to help reduce the drag.

If the clutch is hot from a previous, very recent spool-up, or a prolonged attempt due to perhaps forgetting to lower collective or other factors, it may be difficult to achieve enough friction to “join the needles”. Don’t be too persistent, you may overheat the clutch. It’s best to allow it to cool and then try again.

Max RoC

JetExec Helicopter Limitations

Even though the JetExec is capable of climbing at 2000 fpm, it has been decided to limit the maximum Rate of Climb to 1,500 fpm at Gross Weight (and max. EGT of 1180ºF). This should keep a good safety margin with respect to maximum torque figures on the drive train and rotor hub/blades.

The above procedures are no more complicated or critical than for any certified turbine helicopter. If for example, you start a Bell 206 the wrong way, you will cook the engine and if you fly it without close attention to instrumentation you could over torque the drive train and/or cook the engine. The start up for a Bell 47 (non-turbine) also has a set procedure that must be closely followed.

JetExec Advantages

Why Build a JetExec or do the Conversion?

-

The turbine provides smooth power and plenty of it. Rated at 150+ shaft H.P. you have the power available when you need it.

-

Turbines are less likely to fail, need little or no warm up and sound just great. Be in the air in two to three minutes. They will burn a variety of fuels, RPM is controlled by a governor system and being a Lifetime engine, they are good for 6,000 flights.

-

The new power train in the JetExec Conversion Kit uses gear reductions for the primary drive. The RW secondary and all the belts, chain and oil bath are no longer required. One cog belt is used for the shaft driven tail rotor and TR authority is improved due to reverse direction of rotation and slightly higher RPM.

-

Refuelling is quicker and easier with just one high flow fuel point.

-

Endurance is increased from 2 hours to 2½ hours.

-

All the flight controls in the JetExec remain the same as the original Rotorway Exec and there are very few frame modifications required.

-

Parts are available, standard and interchangeable.

VIDEO: Joe’s turbine helicopter

VIDEO: Intense flying demonstration

VIDEO: Rotorway JetExec Helicopter

INFORMATION COURTESY: http://www.jetexec.info/index.htm

Can the Rotorway exec 90 Helicopter.. Has a K.I.S.S. Aviation Jet Exec Turbine kit,be registered under the microlight

Every country has it’s own version of an “answer” to this question. It’s best to contact the relevant authorities in your country for the correct information. For example, I have read in one country the helicopter “could” be registered in the homebuilt category – BUT – you legally needed a full turbine rating to fly it?

Dear sir

I’m looking for drawings for building my own JetExec helicopter that is powered by a Solar T62-32 turbine.

I am Kris Philipsen 24 years old from the Netherlands, and I think your helicopter building technology is really amazing! And after watching your fantastic achievements, I started to believe that I can take on the challenge of building my own helicopter.

I would like to start building my own helicopter this year, since I’ve always dreamed of building something that I can really fly with, I now see my chance to make a start on this. In addition, in the distant past my grandfather once attempted to build his own helicopter that actually got off the ground for a while, but problems with the tail rotor never made it possible to fly with it. And now I think it is partly my task to successfully complete this assignment.

After graduating from my technical education in Belgium, I started working for 1.5 years in a machine factory as a CNC milling machine operator where they cast aluminum parts and then process CNC for robots, medical equipment and oil refineries.

In November 2018 I started my own metal company called

Primet (Philipsen revision innovation metal). I bought a CNC milling machine and together with a lathe from my father I now make mechanical parts for industrial applications every day.

Since I am quite busy keeping my business running, I want to build my own helicopter from existing drawings. This allows me to immediately start producing the necessary parts on the machines at home. And I promise you that when I get the chance to build the helicopter, I will personally visit you in the summer of 2020 for a meeting and buy a Solar T62-32 turbine engine.

I sincerely hope that you can help me with this.

With best regards,

Kris Philipsen

You can also call me on 011-31-6-401 24 368

Hi Kris, we only publish these articles, you will need to contact these people: http://www.jetexec.info/

Dear sir, I plan to purchase a 162F, most are piston engine. Where can i find a drawings to install a solar titan T-62-32

BEST REGARDS JEAN

https://jetexecinfo.rdswebs.com/

NO ME GUSTA ESE FILTRO DE RESPIRACION ENCIMA DEL TANQUE DE COBUSTIBLE ,PUEDE ACUMULAR VAPORES DENTRO Y EXPLOTAR CON ALGUNA CHISPAJEUS EN EL ARRANQUE.

TRANSLATION: I DON’T LIKE THAT BREATHING FILTER ON TOP OF THE FUEL TANK, IT CAN ACCUMULATE VAPORS INSIDE AND EXPLODE WITH SOME SPARKS AT STARTUP