Popular Kit Helicopter Public Display

ARTICLE DATE: October 1994

June is traditionally graduation month, and Dennis Fetters and his wife, Laura — who own Revolution Helicopter Corp. in Excelsior Springs, Missouri — feel they’ve just completed a four-year education like nobody gets in college.

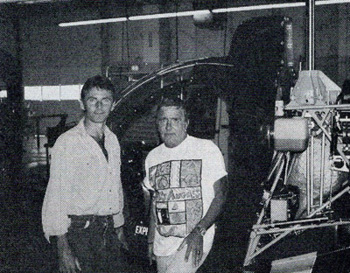

Saturday, June 25, was the culmination of the helicopter adventure that began in 1990 as Dennis took steps toward kitting the Mini 500, a quick-build, single-seat sport machine. The several days preceding the June 25 public open house at Revolution’s 22,000-square-foot factory in Excelsior Springs included seminars and demonstrations for the company’s dealer network.

All 18 of the U.S. dealers and half of the 12 foreign distributors and dealers attended, including those from The Netherlands, Canada, Japan, Italy, France and England. With delivery of the first three Mini 500 kits just a few weeks away, dealers watched as a kit was partially assembled — with most major components attached — in a total of 8 work hours by two employees.

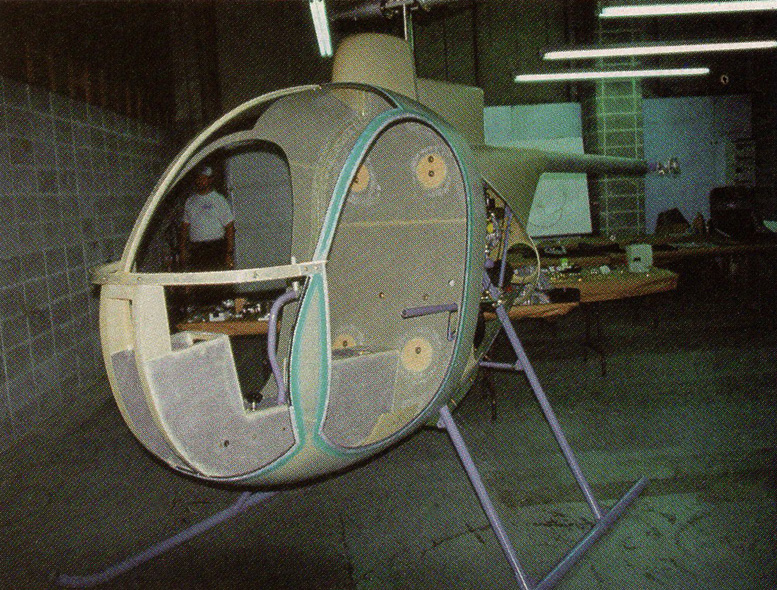

Most parts are completely fabricated and anodized or painted. Prepreg composite parts — including the eggshell-shape fuselage — come out of the molds exceptionally smooth, requiring only light sanding before applying primer and final paint. Everything needed to build a Mini 500 except for paint is included in the kit.

Flying…and More Flying Demonstration of the prototype Mini 500 by company pilot/helicopter CFI Brian Thomas was featured. But the icing on the cake for 19 dealers and customers was a chance to fly the little helicopter themselves.

Company pilot Brian Thomas shuttles the Mini 500 between the factory and Excelsior Springs Airport. By the end of the open house, the prototype had logged 135 trouble- free hours.

Those who came with a helicopter rating and recent currency in the Robinson R-22 (the most common trainer) were evaluated by Thomas in an R-22 rented for the event — and then talked through first Mini 500 flights by Dennis Fetters with a handheld radio.

All 19 succeeded in flying the world’s only completed Mini 500 just weeks before the Oshkosh fly-in. How’s that for confidence in one’s product and instruction? Previous helicopter experience among the fliers ranged from thousands of hours and instructor ratings down to Steve Thomas (no relation to Brian) from Virginia Beach, Virginia.

A fixed-wing pilot, Steve got interested in helicopters less than two years ago, got his rating in an R-22 late in ’93 with a total of 41 hours of helicopter flight time, and completed the required 2-hour R-22 refresher shortly before traveling to Excelsior Springs.

Upon arrival, he had a total of 43 helicopter hours in his logbook. Despite a lot of taildragger airplane time, Thomas found helicopter training “a lot harder than it looks. It’s a challenge.”

Steve worked with Brian Thomas in the rented R-22 until he was smooth. Manning the Mini 500 for the first time, he said he was nervous (a condition admitted by all the neophyte Mini 500 pilots) but managed to relax and enjoy 10-15 minutes of hovering, pedal turns, air taxi, takeoffs and landings. (Other pilots said Steve’s flying was among the best.)

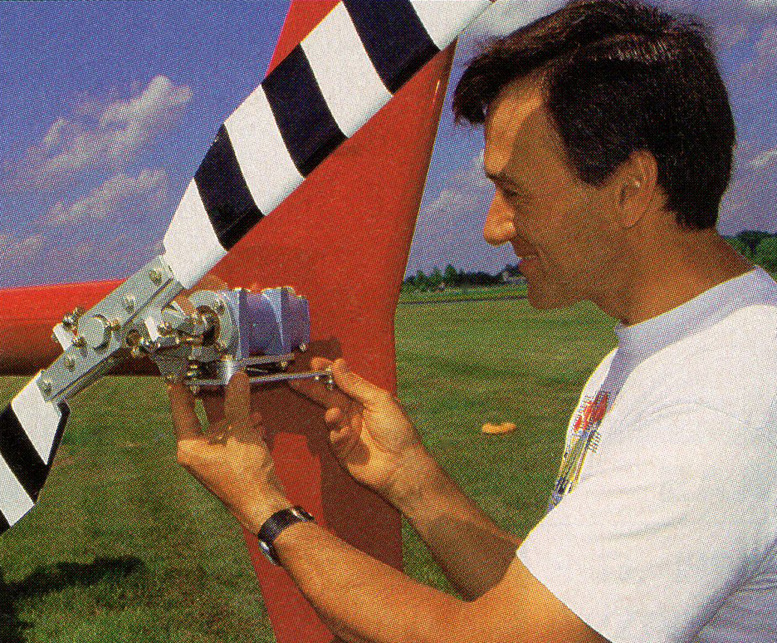

Mini 500 dealer Maurice Boyer from Montreal, Canada, examines the tailrotor gearbox on the prototype.

Because of his size (6 feet 4 and 220 pounds), Steve Thomas found he had to add throttle to keep rotor rpm in the green, and increasing rpm into the high green area eased the work. “It’s fantastic,” Thomas said. “The sight picture is totally different from the R-22. The Mini 500 is very smooth on the controls and less sensitive than the R-22.”

Steve Thomas’ kit is No. 101, and he’s expecting to receive it next winter. “If it’s delivered by Christmas, as the factory says it might be, that would be my best Christmas present. But Dennis [Fetters] is always coming up with new ideas to make something operate better or make it lighter.”

“As long as he is making improvements to the craft, I’m willing to sit back and wait,” Thomas said. Steve Thomas and I have agreed to correspond about his Mini 500 building and flying experiences, and you will read about them in future issues.

Here They Come!

Following the three days of dealer and customer events, the general public responded to local advertising and arrived on Saturday by the carloads.

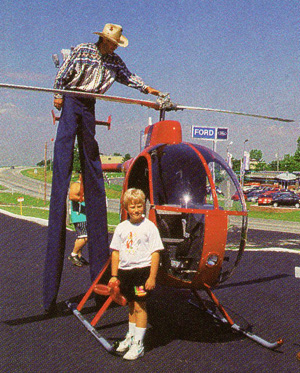

Laura Fetters, her sisters and mother helped with the arrangements, which included factory tours, a preview of the new Mini 500 video, flight demonstrations by Brian Thomas from the pad alongside the company showroom, ribbon-cutting by the president of the Excelsior Springs Chamber of Commerce, a flight in the R-22 for city Mayor Jim Robertson and others, recruiting for cadets and seniors by a nearby Civil Air Patrol squadron, free snacks and soft drinks, plus special treats for the children: a stiltman and a clown who folded balloons into airplane and animal shapes.

By the 5 p.m. closing time, 549 adults had signed the register (many more than 600 people actually attended), the total time on the Mini 500 prototype had climbed to more than 135 flight hours, and the Fetters family was ready to relax.

Tensions were maintained Saturday night, however, by a severe storm that put out the lights in Revolution’s part of town and spawned a no-significant-damage tornado that touched down 2 miles north of us. On Sunday morning, Brian Thomas and Dennis Fetters offered the employees and their families helicopter rides in the R-22 at the Excelsior Springs Airport.

A Bit of Background

Following Dennis Fetters’ design, manufacture and marketing of the Air Command line of gyroplanes, he concentrated on producing a single-seat kit helicopter. Associated for a time in 1990 with Augusto Cicare of Argentina, Fetters demonstrated Cicare’s open-frame, Rotax-powered single-seater at Oshkosh ’90.

A falling-out with Cicare resulted in Fetters developing and patenting parts of his Mini 500 design, including the rotor control system, which eliminates the weight and complexity of a conventional swashplate.

Fetters’ new Revolution Helicopter Corp. began taking 10% deposits on the Mini 500. A first mockup was displayed at the Sun ‘n Fun in April, ’91, and he demonstrated a flying prototype at Sun ‘n Fun ’93.

Kansas City area flooding of the Missouri River interrupted developments in ’93: A spring flood put 4 feet of muddy water into Revolution Helicopter facilities at Liberty Landing Airport.

After cleaning up the mess, Fetters bought flood insurance — and collected on it after last summer’s flood waters covered Liberty Landing with 14 feet of water and swept away or destroyed most of the tools and tooling for the Mini 500 — and caused the company to miss Oshkosh ’93.

Fortunately, paperwork and computer files were saved. Last fall, Fetters noticed a vacant car dealership on the west edge of Excelsior Springs, which was his childhood home town.

Stiltman Doug McCook shows how easy it is to examine the top of the Mini 500 main rotor hub.

With the help of a FEMA loan and the insurance proceeds, he began converting it for his helicopter development, marketing and production facility. Neighbors, including a car dealership across the street, were not keen on nearby helicopter operations, Fetters says, until the Mini 500 began flying from the site.

Noise is exceptionally low for a helicopter (less than many trucks on the street), and the machine does not kick up debris from the paved lot. Neighbors are no longer complaining, Fetters says. The car dealership sent a bouquet for the open house.

A Few Details

Designed to operate with a 67-hp Rotax 582 two-stroke, dual-ignition, liquid-cooled engine, the Mini 500 was first equipped with an electric fan to cool the radiator during hovering. But cooling proved inadequate.

The new system uses a small amount of power from the engine to drive a fan directly, and Fetters said the system stays within limits (below 200°F) with a 235-pound pilot hovering on a 110°F day.

The Mini 500 operated without a failure and without adjustments during Sun ‘n Fun last April, and Brian Thomas reported coolant temperature of about 160°F when hovering in air temperatures near 90°F.

At the Excelsior Springs Airport, the Mini 500 prototype demonstrated its climb rate of up to 1100 fpm, hovering and standard autorotations, quick-stops, its top speed of 95 mph, and pedal turns in gusty conditions.

No adjustments were made all week, Thomas said. “All we did was add gas.” The two-stroke Rotax 582 engine is equipped with an oil injection system that varies the ratio of oil to gasoline depending on rpm.

The oil tank is large enough to lubricate many tankfuls of gasoline, and its level is checked on each preflight. With its 15-gallon fuel tank, the Mini 500 claims a 225-statute-mile range at a 75-mph cruise speed.

No-reserve endurance is 3 hours. Hovering ceiling – both in and out of ground effect — is listed as 7500 feet, and service ceiling is 10,000 feet. Maximum gross weight is 820 pounds, leaving a useful load of 400 pounds.

The composite rotor blades — made by Revolution Helicopters — span 19 feet. Composite prepreg parts are also made by the company — with materials kept frozen until they are pressed into molds that are vacuum-bagged and heated to form and cure.

Kits cost $24,500 and will come complete with an electrical system, navigation and landing lights, all instruments required for VFR flight, and a wiring harness to put it all together. Estimated building time is 40-60 hours plus painting.

If the instructions are as good as the finished parts displayed at the open house, building should be as easy as with modern radio-controlled helicopter kits. Many of these can be assembled and flown in a week of spare time.

Back to Work

With the open house behind him, Fetters said his next project is to complete work on the construction manual. While he taps computer keys, his personnel and production managers gear up to fill more orders. The company expects a flood of new orders beyond the current list of 170 once shipments begin and the first customers build and fly their aircraft.

From this vantage point and barring further disasters such as the floods of ’93, my guess is that the optimism is justified. Also worth noting: The new facility is hundreds of feet above the Missouri River high-water mark.

Eight man-hours on a Mini 500 kit results in accomplishing this, according to witnesses.

FIRST REVOLUTION HELICOPTER CUSTOMER FLIES FACTORY MINI-500

ARTICLE DATE: September 1994

Mr. David Bridgman, president and owner of Australian Minicopters in Queensland, Australia, holds the distinction of being the first Revolution Helicopter Corp. (RHC) customer to fly the, factory Mini-500 helicopter at the RHC facility in Excelsior Springs, Missouri, on May 11, 1994.

“Flying the Mini-500 for the first time was truly a dream come true,” said Bridgman. He placed his first Mini-500 deposit early in 1991, when RHC began accepting Mini-500 deposits, because the aircraft “looked more promising than any other design available in the market.”

Bridgman has only logged 107 total hours in Robinson R22 and Brantly B-2B. The Mini-500 is so easy to fly that even low-time pilots can quickly transition into the Mini-500.

“As a helicopter, the Mini-500 surpasses expectations, it is strong, powerful, steady, and transition for the new pilot is easy providing one takes it slow and, after 45 minutes, most pilots will feel very much at home in this state-of-the-art machine,” he said.

The Revolution Mini-500 flew for the first time at this year’s Sun ‘n Fun Fly In.

Bridgman, representing the Mini-500 in Australia, is one of the ten already established RHC foreign distributors. After researching the light rotorcraft market, Bridgman decided to visit RHC factory in early 1991 to see an early mockup version of the Mini-500.

He was impressed with what he saw, and decide d to get involved with RHC through the distributorship program. “As one of the early foreign distributors, I have been with Revolution through most of its ups and downs, and now to experience the final result makes it worthwhile,” Bridgman says.

As of today, a total of 160 Mini-500s are on order right now, and Revolution is ready to start delivery to its customers early this summer, with 49 percent to be exported to foreign countries. Bridgman is the fourth largest foreign distributor ready to accept delivery of his initial nine aircraft.

Outside the United States, other big markets include Spain with 13 aircraft on order, Italy and Taiwan with 10 each, and Canada, England, New Zealand, The Netherlands, Japan and France each importing six new Mini-500s by year-end. Bridgman’s sales should be even more impressive this year, with his first Mini-500 scheduled to arrive in Australia early this summer.

With a growing mailing list of over 2600 names, Bridgman estimates that he will have twelve more Mini-500 orders immediately upon the arrival of his first Mini-500 in Australia. “I have many people waiting, and they will fly in from all over Australia to see the Mini-500,” he said.

The main need for this aircraft in Australia is for ranching purposes, followed by recreational. “You can get a Mini-500 in Australia with what you pay for insurance on an R22,” said Bridgman.

The complete Mini-500 helicopter kit is available in the United States for $24,500 USD. A deposit of ten percent is all that is required at the time the order is placed, with the balance due before shipping.

Be the first to comment on "Revolution Helicopter Mini 500 Public Debut"